9 Types Of Drawer Slides: What Design Styles to Use

It’s easy to understand why selecting the best drawer slide is crucial given how frequently you will open a drawer day to day. Your drawer slide selection will be influenced by a variety of aspects, including the type, cost, features, finishes, and perhaps just a preference for the way a certain slide feels in your hands.

Chests of drawers, cabinets, and other pieces of furniture frequently have drawer slides. A piece of furniture will be equipped with at least one slide if it includes one or more drawers. A mechanism called a drawer slide enables a drawer to glide into and out of the piece of furniture where it is mounted.

A set of sliders hold each drawer in place. A drawer will glide open along these rails whenever you pull it out. Although this technique of movement is shared by all drawer slides, there are many different styles available.

Quicklook: Different Design Styles of Drawer Slides

| Side Mounted | Center Mount | Under Mount | Ball Bearing | Soft Close | Roller |

|---|---|---|---|---|---|

| Attached to sides | Single slide in center | Hidden underneath | Uses ball bearings | Closes gently | Uses wheels |

| Common | Light-duty use | Sleek look | Smooth operation | Prevents slamming | Basic option |

| Various capacities | Space-saving | Full extension | Heavy-duty capable | Often combined with others | Economical |

Drawer Slide Design Styles

Here we share the different drawer slide design styles with their mounting installation type, advantages, disadvantages and uses.

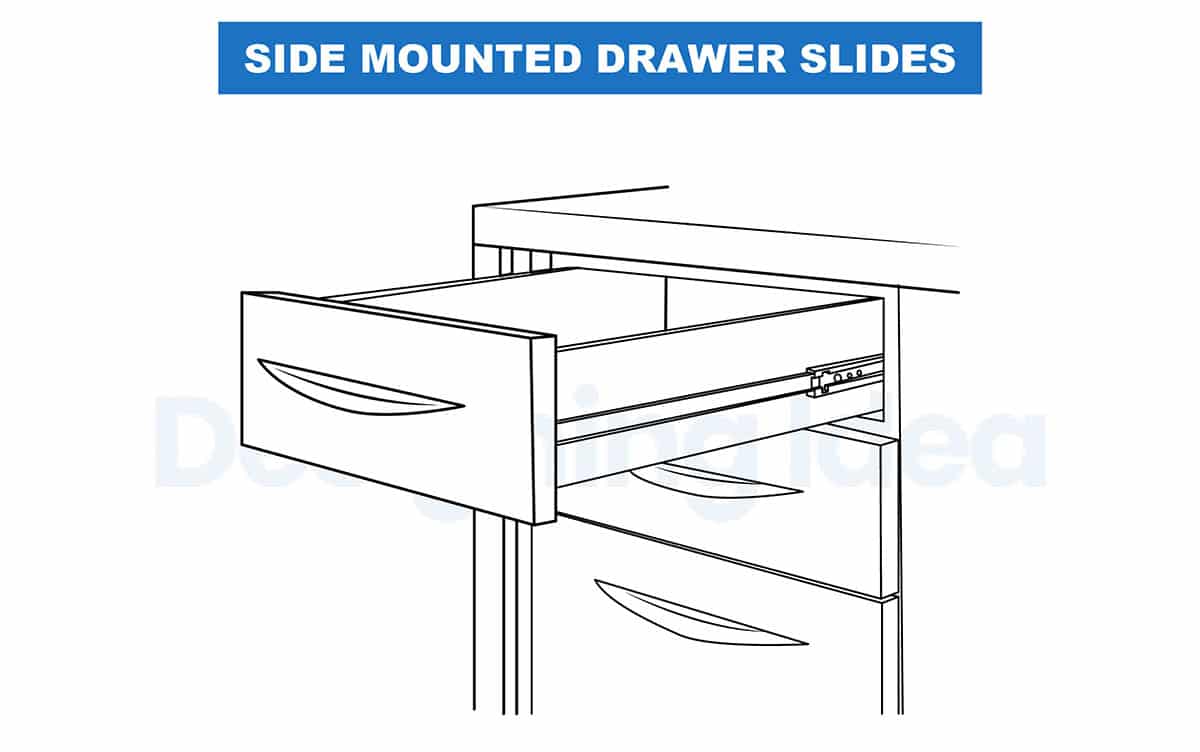

Side Mounted

Side mount drawer slides are quite a common component in cabinet and furniture design. They are simple to install and adaptable, with numerous choices including self-close, soft-close, and touch-release.

Moreover, side-mount glide tracks are installed on the side of the bureau frame, just like their name suggests. They are typical on a selection of products, including kitchen cabinets, toolboxes, and storage cabinets. There is quite a good probability that you will use a side-mounted cabinet tracks if you inspect your kitchen right now.

Installing new Euro – style drawer slides in a face – frame cabinet is usually a bit of a challenge. Half of each slide goes on the side of the compartment, and half mounts to the cabinet. – Refacing Cabinets: Making an Old Kitchen New, Herrick Kimball

However, there are usually two types of side-mount sliders – ball-bearing models and epoxy or Euro models, which have nylon rollers that move along tracks.

The advantages of ball-bearing side-mounted types include their quiet operation, large weight carrying capacities, and possibilities for complete expansion and over-travel.

Additionally, they frequently come with a detent as default, which prevents the compartment from slowly opening if the cabinet is marginally out of level.

The side-mounted models with epoxy coating have an opening detent that keeps the storage space open for convenient access while you operate as well as self-closing action. These tracks need a space between them and the edges of the cabinet opening, typically 0.5 inches.

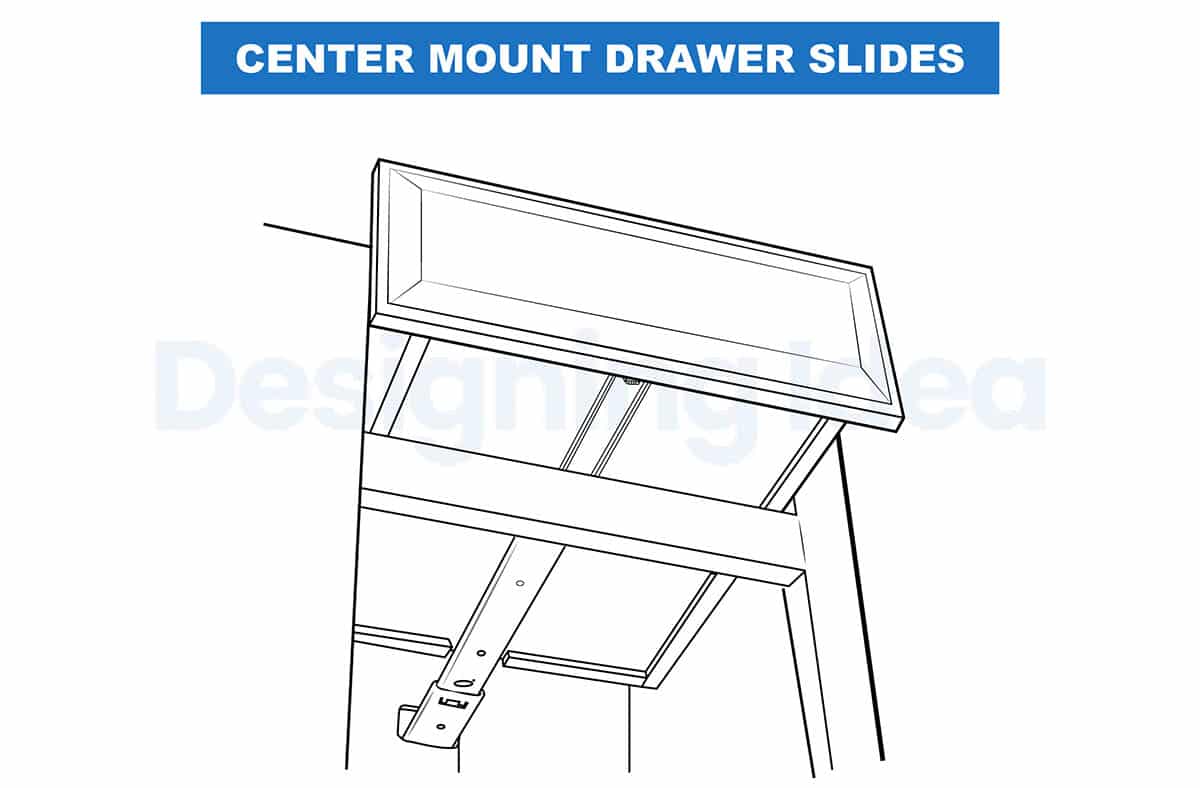

Center Mount

Center-mount compartment slides represent a more traditional form of sliders that continue to be in operation today, but they are more commonly sold as substitutes for older cabinets.

They are completely covered just like under-mount cabinet slides, but rather than being attached beneath both sides of the storage box, a solitary slide runs down the center. Center-mount glide mechanisms are designed for lightweight applications and are positioned underneath the compartment centers.

Moreover, center mount tracks are recommended if the storage case is relatively lightweight and is equipped with unusual joinery such as finger joints. Center-mount slides are often only accessible in 3/4 extension and do not have features like soft-close and self-close due to their restricted weight limit.

Single center mount storage case tracks are widely available for purchase at most cabinet hardware stores. They are usually offered in both traditional wood and ball-bearing models. The necessary clearance is determined by the width of the slide.

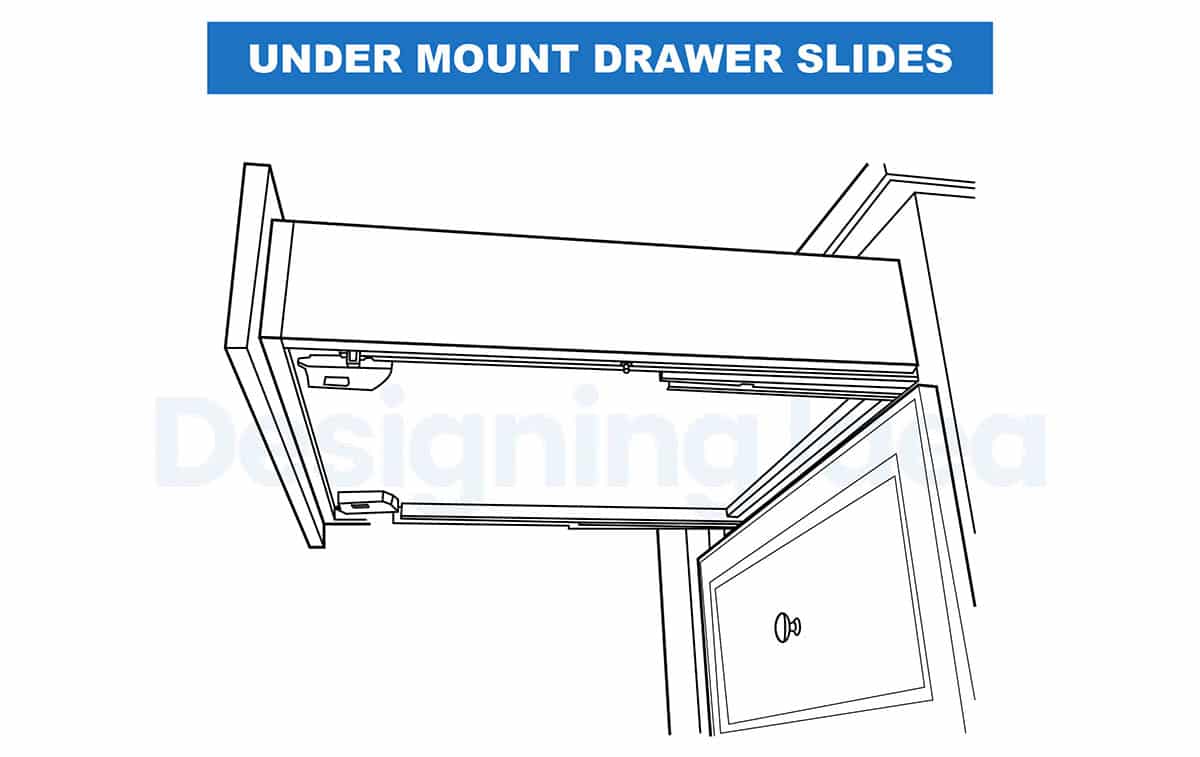

Under Mount

Under-mount drawer slides are hidden beneath the storage box. They offer more stability than side-mount motion tracks. Under-mount drawer gliders enable the runners to slide open and close freely. Furthermore, they can bear greater weight and give more support than cabinet gliders situated on the storage box’s sides.

Furthermore, under mount drawer slides have two advantages over side-mount drawer slides – they are completely obscured underneath the drawer and, because they do not require quite so much space on the sides for clearance, they provide considerably greater storage space within the drawer.

Nonetheless, take into account that you will lose some box height within the drawer because the slides necessitate additional room under the storage case. Aside from that, under mount sliders are also typically equipped with high-end features such as soft-close, making them a popular choice for high-end cabinets.

You can check the spec documents if you are installing drawers because they have precise specifications for side thickness, drawer dimensions, and typically necessitate notching at the backside.

See this under mount drawer slides at Amazon [sponsored link]

Under-mount drawer slides are available in a variety of lengths, allowing homeowners to customize them according to their desired cabinet depths.

There are also available full-extension under-mount drawer slides that enable drawers to be extended completely, making it accessible to the drawer’s rear.

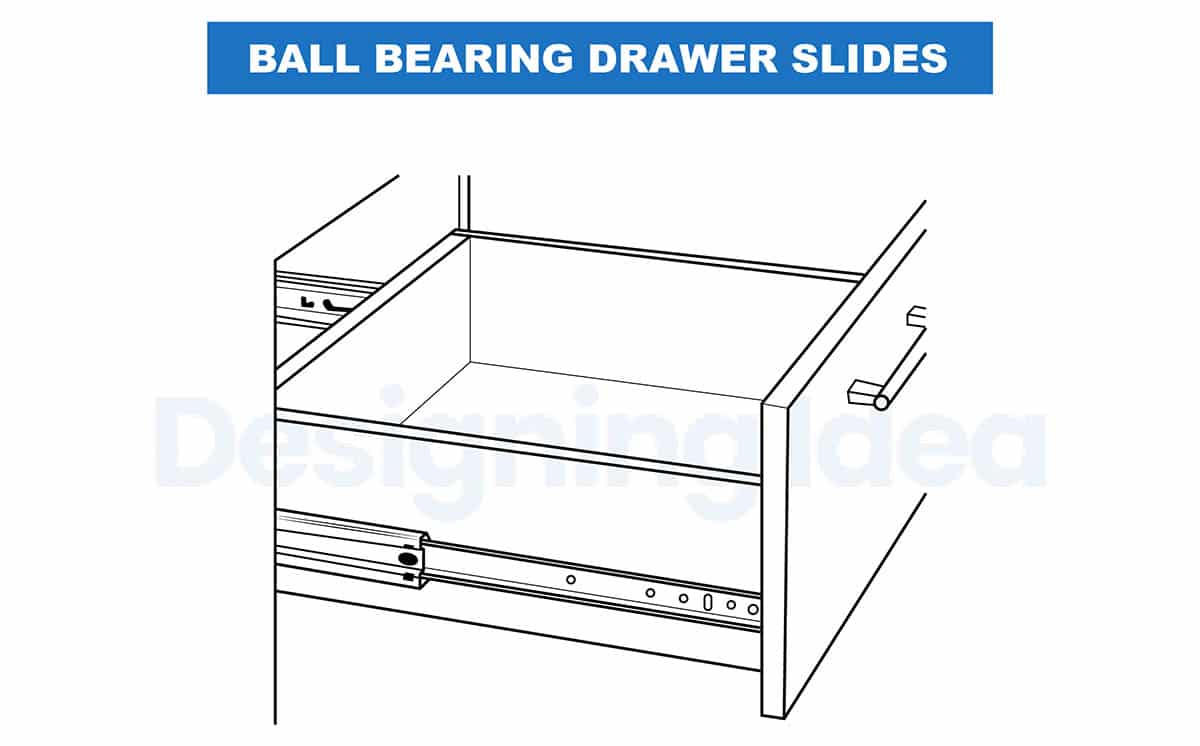

Ball Bearing

Ball-bearing drawer slides are among the most popular types to choose. As the name suggests, these models are distinguished by the use of ball bearings. They have little metal balls embedded in the tracks that minimize friction, enabling drawers to close and open very smoothly.

Ball-bearing track systems are available with one-way or two-way motion. Notwithstanding, the rails are all equipped with ball bearings. Such sliders are much sturdier and have a higher weight-bearing capacity than roller styles.

Progressive motion or telescopic slide versions are the most common ball-bearing options. Progressive motion drawer slides enable silent and slick closing and opening actions since all parts move at once.

Telescoping tracks, nevertheless, are partitioned and move individually in stages, with each portion fully stretching or compressing before initiating the movement of the following portion.

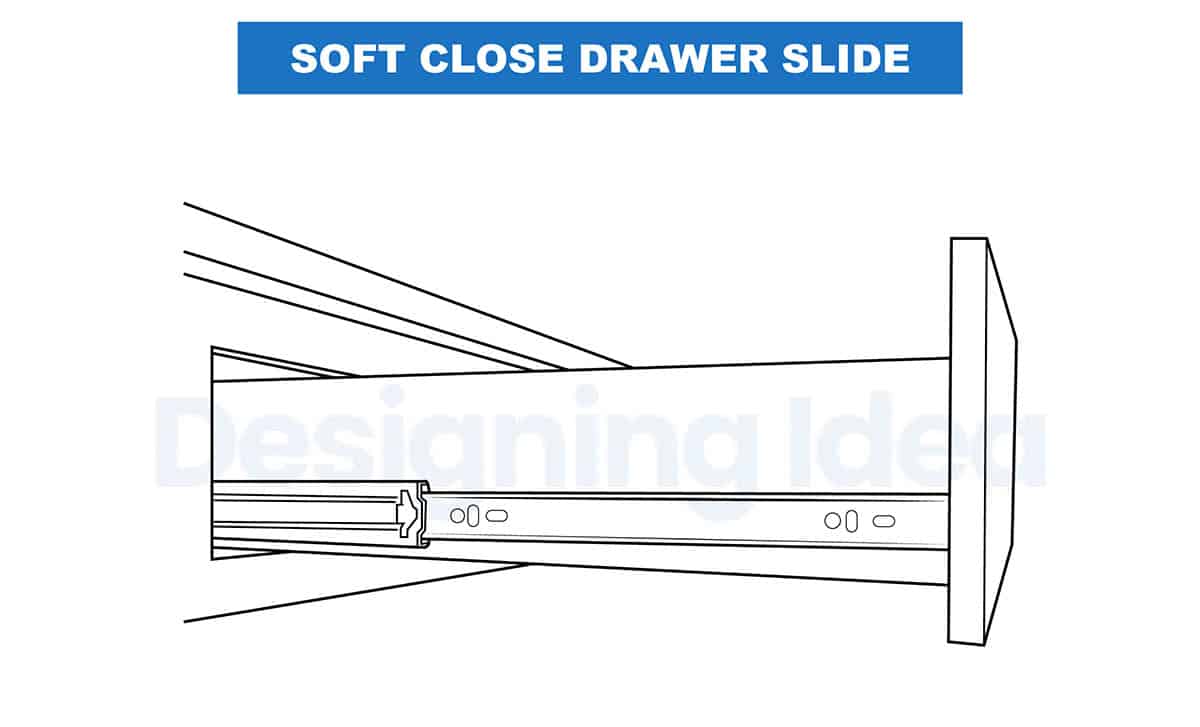

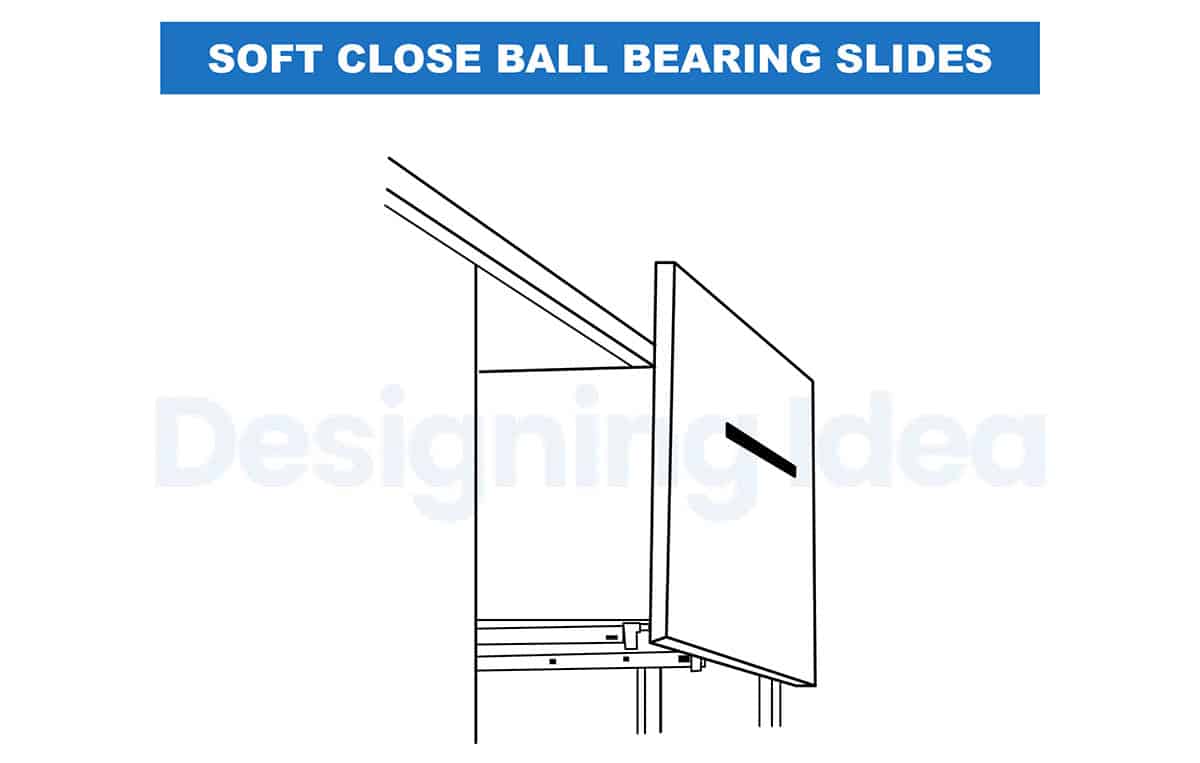

Soft Close

Soft-close ball-bearing slides are employed in a variety of settings, including industrial equipment and home furnishings like dresser drawers.

Such drawer slides’ construction incorporates ball bearings, which increase its durability and capacity to support heavy loads. They can sometimes be employed at different angles and in both vertical and horizontal arrangements.

See this soft close ball bearing drawer slides at Amazon [sponsored link]

In order to provide telescopic action, soft close tracks utilize ball bearings rather than rollers. The cabinet member, intermediate member, as well as drawer member, are typically their three individual elements.

The drawer member is mounted to the moving part, while the cabinet member is mounted to a grounded or fixed part.

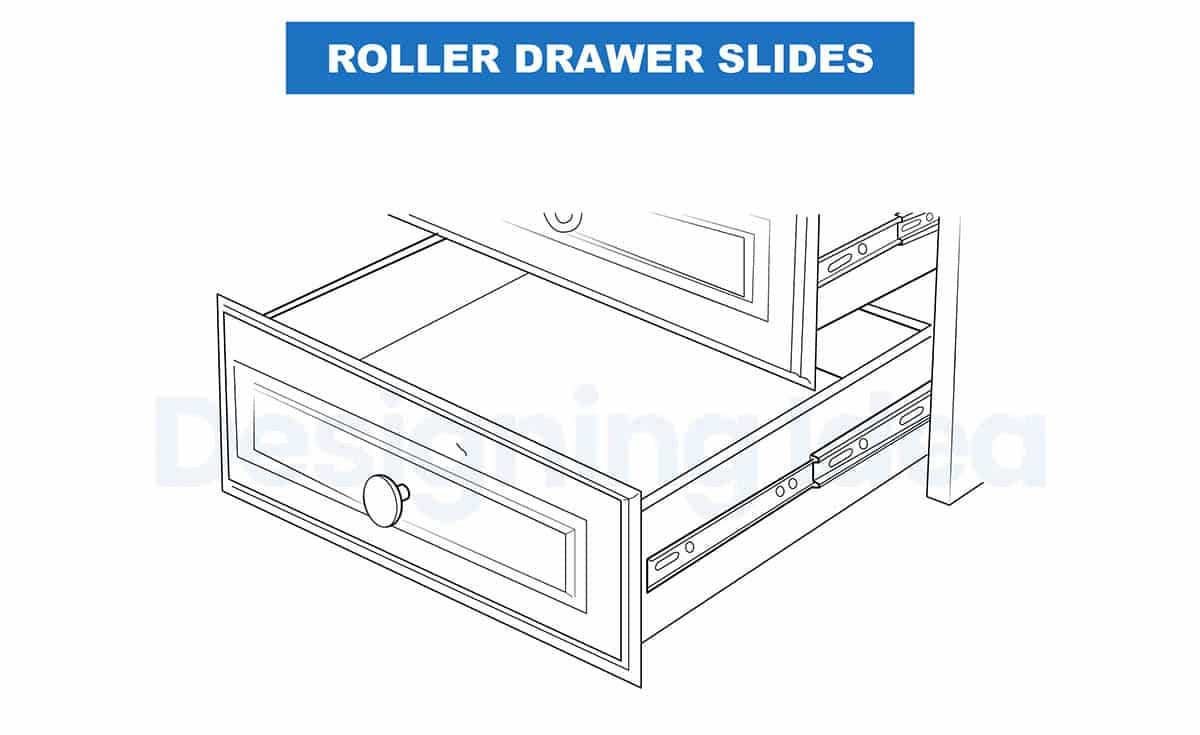

Roller

Roller slides are connected to the drawer box’s edges and include a rolling wheel that allows it to glide backward and forward across the track. This style is commonly found on more affordable furniture pieces and cabinets. They are commonly made up of two bonded, epoxy-coated metal profiles—one attached to the drawer and another to the cabinet frame. They also usually have nylon wheels that enable the profiles to travel smoothly and softly along one another.

These slides are more visible than wood options since they connect to the sides of the drawer and, as a result, will require a false face or an elongated drawer front lip to cover the types of cabinet hardware that are being used.

Roller slides, which are available in either side-mount or bottom-mount, also known as European bottom-mount models, are often utilized for particularly lightweight purposes.

This type is frequently more fragile than the others and is more susceptible to bending under severe pressure. You must also attach roller rails that are absolutely level or the glide will move open by itself.

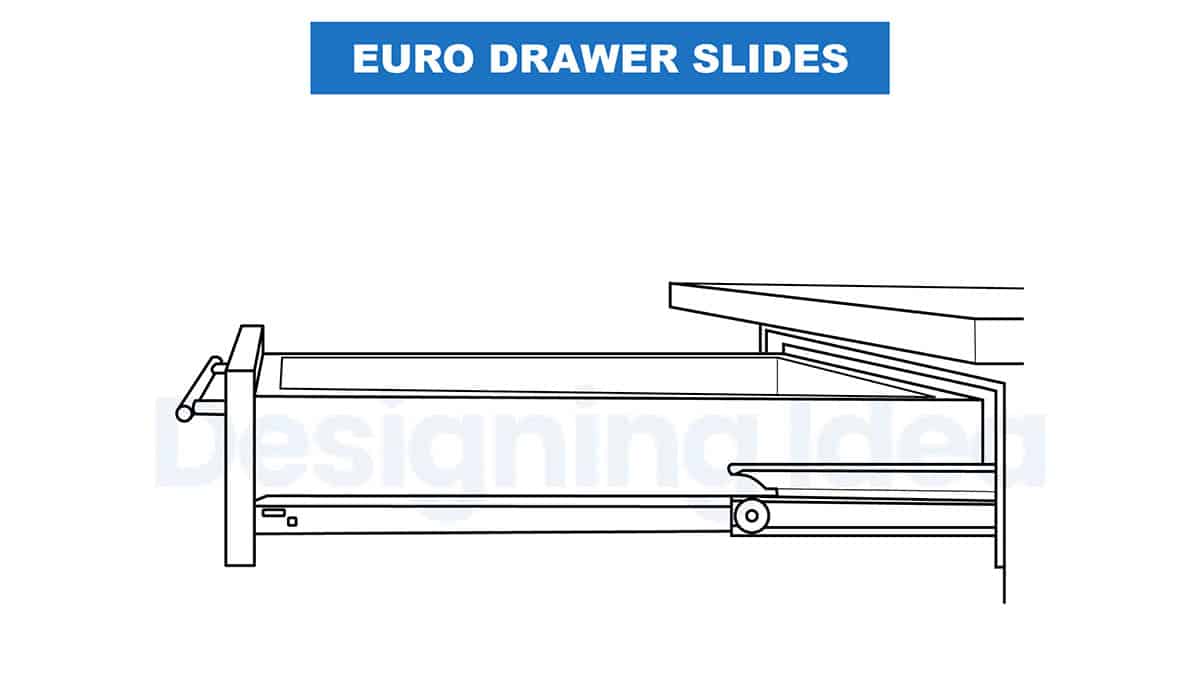

Euro

A Euro drawer slide is an epoxy-coated one-rail under-mount mechanism. A nylon wheel, rather than a ball-bearing mechanism, is used to accomplish pull-out motion. Load capabilities range from 75 to 100 pounds, and such slides can be 3/4 or complete extension.

Euro styles are often affordable, simple to install, and have a decent medium load capacity. They attach to the bottom part of the side as well as the interior of the cabinet.

See these euro drawer slides at Amazon [sponsored link]

Because of their inexpensive cost and simplicity of installation, they are frequently an excellent alternative to other types.

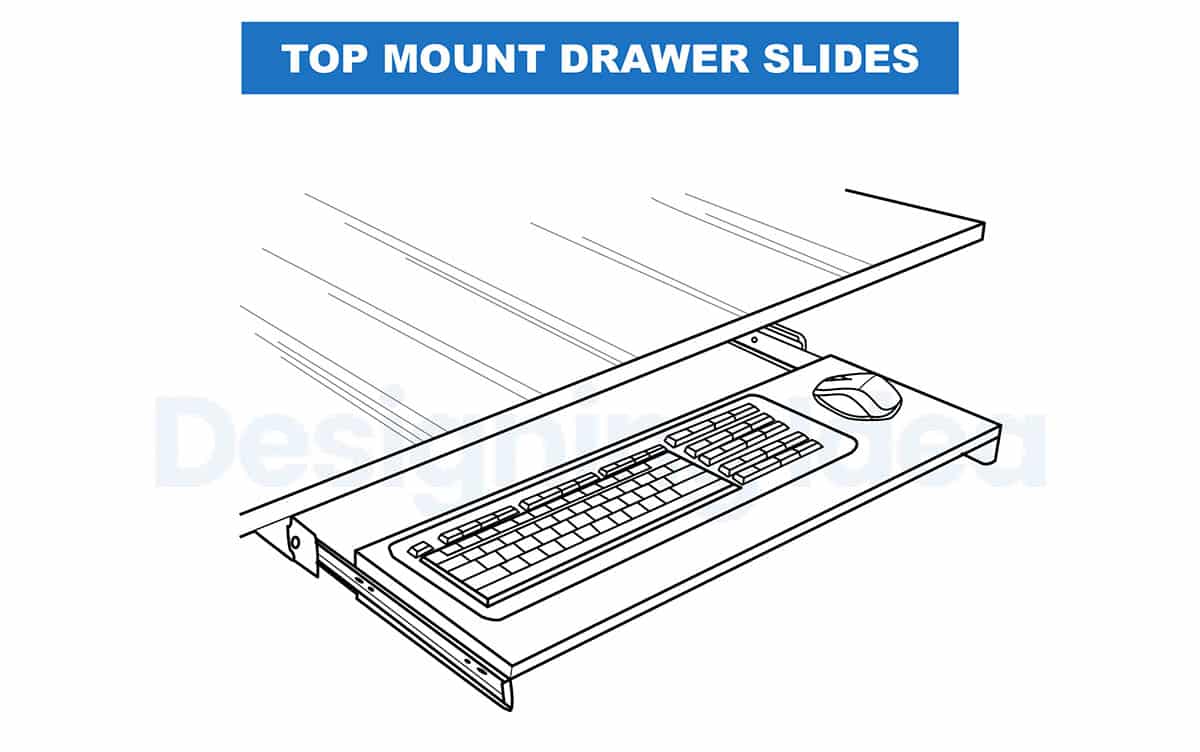

Top Mount

Top-mounted drawer runners or slides are connected to the drawer’s top portion as well as the cabinet opening. Under-mount types are the absolute antithesis of this.

Top-mounted tracks are widely utilized in pencil drawers and keyboard trays that lack sides and bottoms.

See this computer desk with keyboard drawer at Home Depot [sponsored link]

It is important to remember that the drawer and its contents are dependent on the screw that holds the slides, thus its assembly requires a good-quality series of screws.

Slide Materials

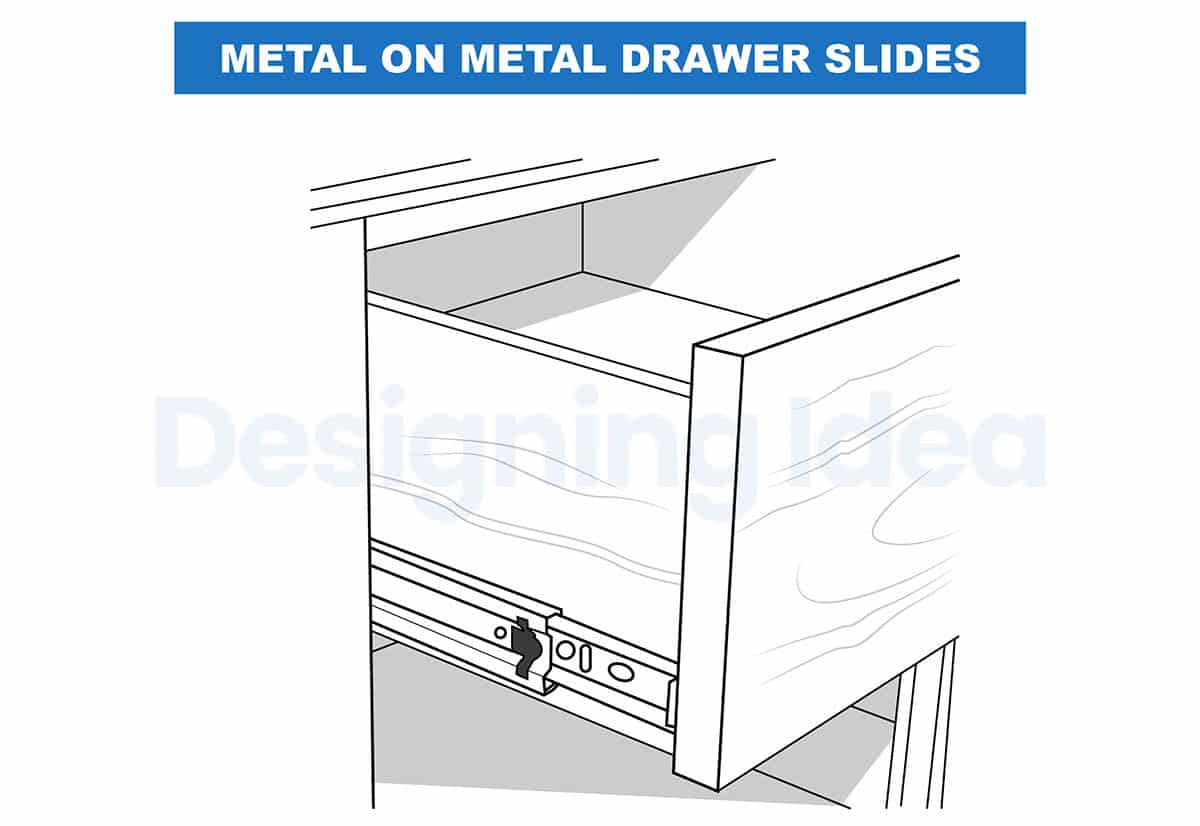

Metal On Metal

Metal-on-metal drawer slides are usually the most ideal material if you are planning on putting a considerable load in your cabinet. The vast majority on the market use high-quality metal slides with stainless steel bearings for smooth operation.

In general, conventional metal-on-metal tracks can withstand sufficient weight for daily usage in the kitchen. These are normally rated for loads ranging from 75 to 100 pounds.

Nevertheless, in other cases, a more formidable metal slide is required. Hence, you have to look for thicker metal options that can withstand greater weight than usual, such as huge types of filing cabinets, pantry pull-outs, or tool cabinets. These are made of tougher metal and have additional ball bearings to increase sturdiness.

Wood On Wood

Cabinet and furniture manufacturers employed wooden slides solely before the introduction of more advanced plastic and metal drawer slide designs.

These elements, made out of wood strips, act as horizontal rails upon which drawers sit and open. Depending on the cabinet or drawer front, supports can be installed on the wood-on-wood glides to aid in the movement of the drawers whenever they close and open.

The use of wood-on-wood slides in furniture and cabinet items necessitates precise manufacture and installation to provide for smooth drawer motion without being excessively loose or overly tight.

Although getting the right fit is tough, it culminates in a finished drawer that does not require any extra hardware or false face components.

Nevertheless, despite the stylistic benefit of employing wood-on-wood cabinet motion tracks, the difficulties of establishing a well-balanced drawer fit as well as the constraints on extension, make it unsuitable.

Full extension is not achievable with wood tracks without sacrificing stability and their proclivity to stick, particularly in humid situations, which makes them less ideal to be used than metal cabinet sliding components.

Slide Sizes

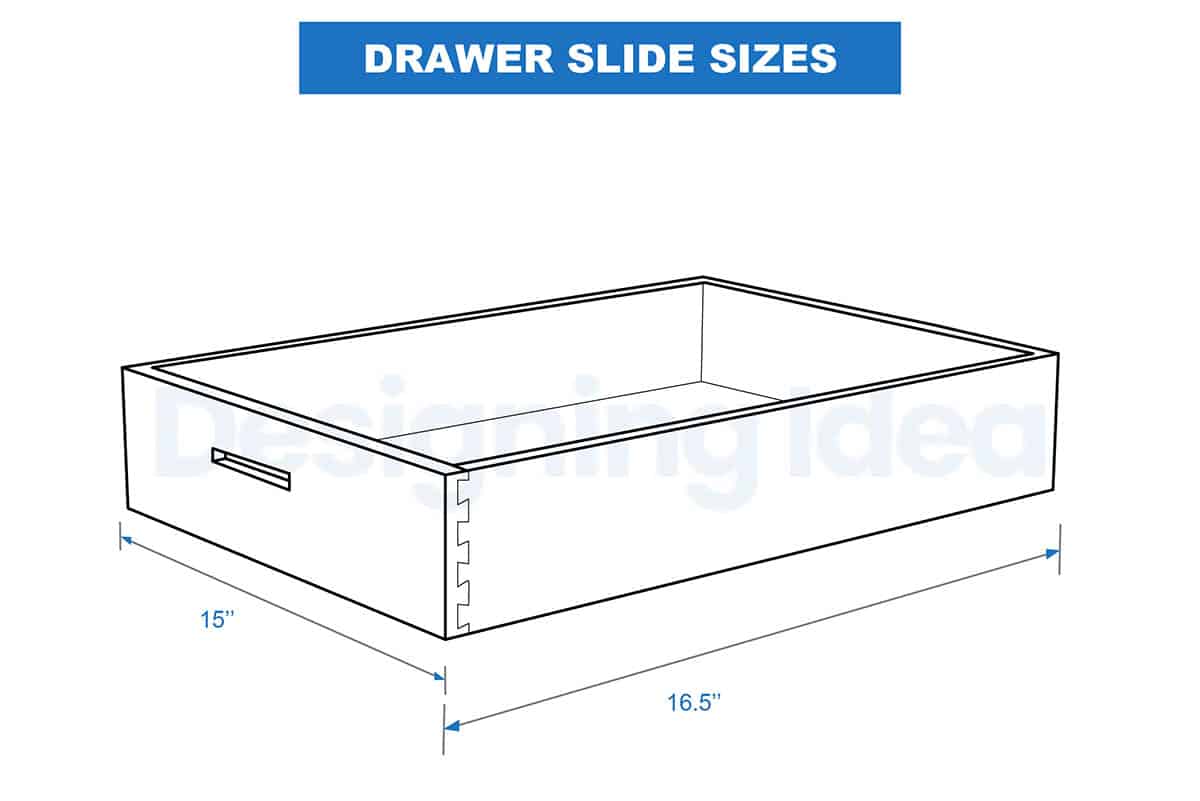

The most important consideration when selecting a drawer slide is its depth. If it’s either excessively thick or thin, it will not function properly. It is preferable to measure the cabinets rather than refer to the preceding slides to determine the necessary depth.

For instance, if the drawer width is 15 inches and the drawer slot depth is 16.5 inches, the total space available for both glides becomes 1.6 inches. This implies it requires two 0.75-inch-deep container motion tracks .

Take note that buying slides that are very thin is usually better suited because a shim can be placed between the cabinet walls and the tracks to fill in the gap between them.

The drawer slide’s length is also important. Ones that are excessively long or short might not open or close correctly, causing them to get overworked. Hence, you have to choose the longest track that will fit without reaching the drawer depth.

Furthermore, it is difficult to install a track taller than the drawer or pull-out. This is particularly the case for mounts that are incredibly thin. When installing thin drawers with a limited mounting area, you can use a tall drawer slide.

Finally, the appropriate drawer width prevents the cabinet motion tracks from flexing or twisting significantly. Wider drawers must be capable of supporting less weight than the weight restriction mentioned.

Most slides do not come with a standard size, although they are not suitable for lateral file drawers. As a result, the width of the drawer must not be greater than the depth of the cabinet.

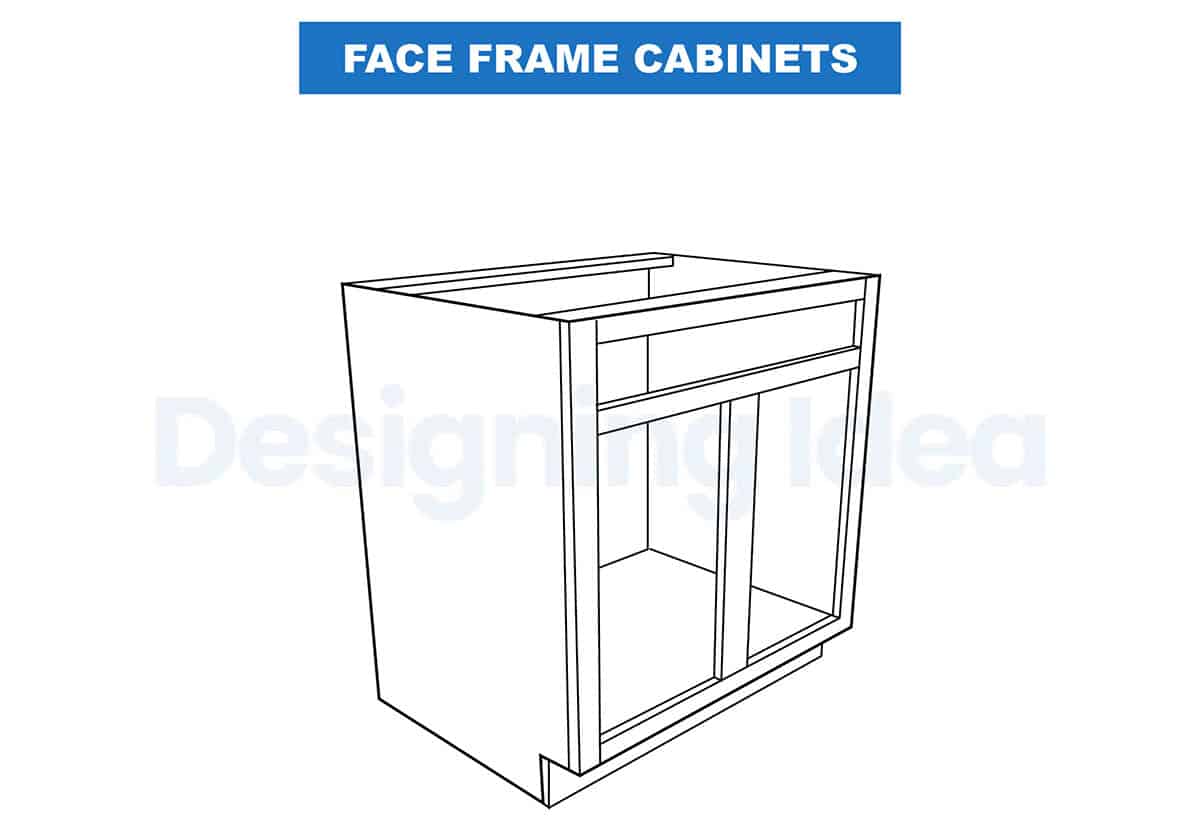

Face Frame Cabinets: A short slide inhibits the drawer from completely opening, while an excessively long track will not fit in the cabinet.

To establish the right length, you have to measure the inner depth of the cabinet behind the face frame and select a slide that is one size shorter.

Frameless Cabinets: Under-mount slides are suitable for frameless cabinets with little horizontal space since they generally take up 0.188 to 0.25 inches per slide.

Another thing to keep in mind concerning under-mount slides is that they need 0.5 inches of clearance both above and underneath the drawer in a frameless cabinet opening.

Frameless cabinetry offers better access to the interior and a bigger opening for larger items like plates, bowls, pot and pans.

Slide Features

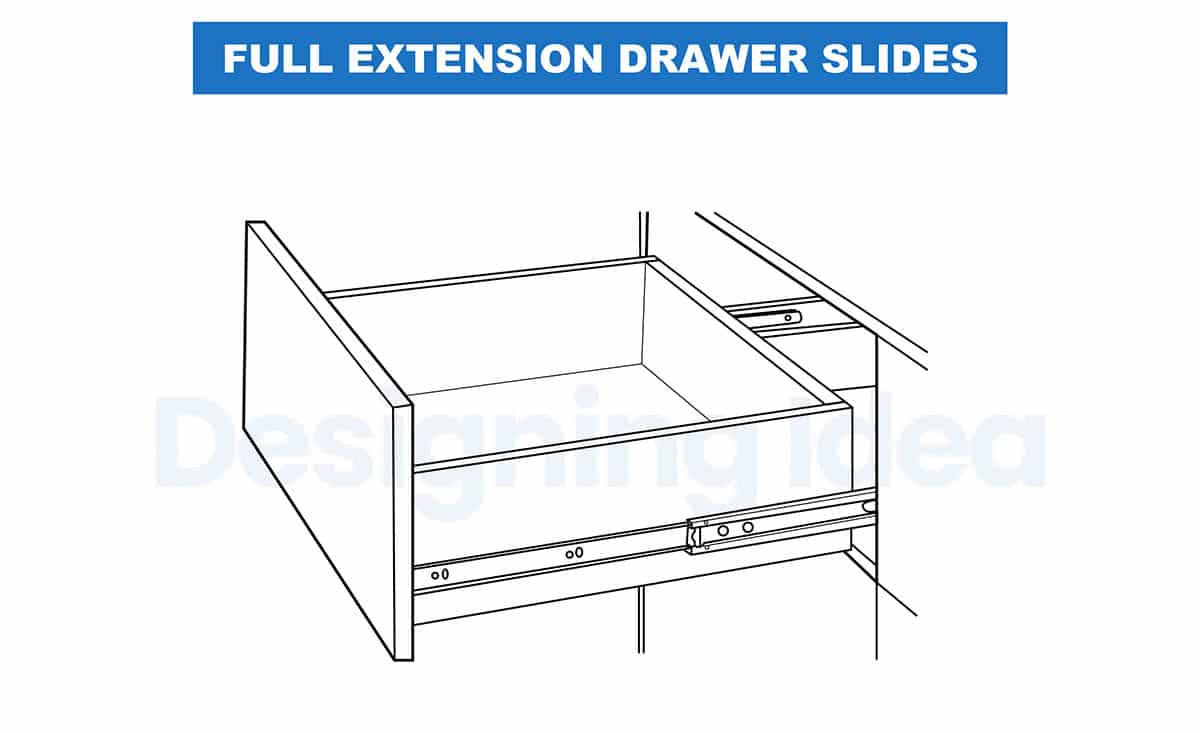

Full Extension

The entire drawer can be easily accessed using full-extension pull hardware. This form of slide is widely available in shops and is the finest choice for the majority of cabinets.

However, you have to verify the load rating to ensure you are not overloading them because they have a tendency to become less durable the more load they are carrying.

In addition, full-extension cabinet motion tracks are ideal for an average homeowner or enthusiast since they enable them to see and access everything within the drawers.

Self Closing

When a drawer is tagged as ‘self-closing’, it means that it will close itself when it gets to the final few inches of its course. When touched too gently, the drawer stays partially open, whereas pressing too strongly causes it to bounce right back.

This problem is solved by a self-closing glide mechanism. A basic self-closing slide shuts the drawer quickly, using either a ramped rail, which is common on epoxy sliding components or using a spring operation, which is, on the other hand, common on telescopic varieties.

A set of slides replaces the normal components in a self-closing drawer slide. Once you insert these tracks, the drawer travels to its hinges and glides back into position. Nonetheless, because it has little influence on closing, this slide is usually not advised for fragile cabinets.

Moreover, self-closing cabinets are ideal for workshops as well as other busy areas where cabinets must be fully closed at all times. However, because it usually creates a sound, it is not suggested in places where peace is essential like baby nurseries or libraries.

Delayed Close Ball Bearing Mechanism

Soft-close drawers have a ball bearing with dampening mechanism that delays the movement of the gliding mechanism so it does not emit a noisy clang. This prevents items from sliding around and making noise within the drawer. It also extends the life of the motion tracks by reducing wear and stress.

In addition, soft-close glide mechanism assist in keeping drawers closed without having to close them firmly by hand. Whenever the cubby reaches a specific position, either a spring or a little ramp that runs behind the slide causes it to close quietly.

Furthermore, soft-close motion tracks are ideal for noise-sensitive environments such as workplaces, libraries, clinics, and high-end establishments.

They are also ideal for sectors such as archives that require the storage of sensitive items. Soft-close tracks are frequently utilized to create child-safe drawers.

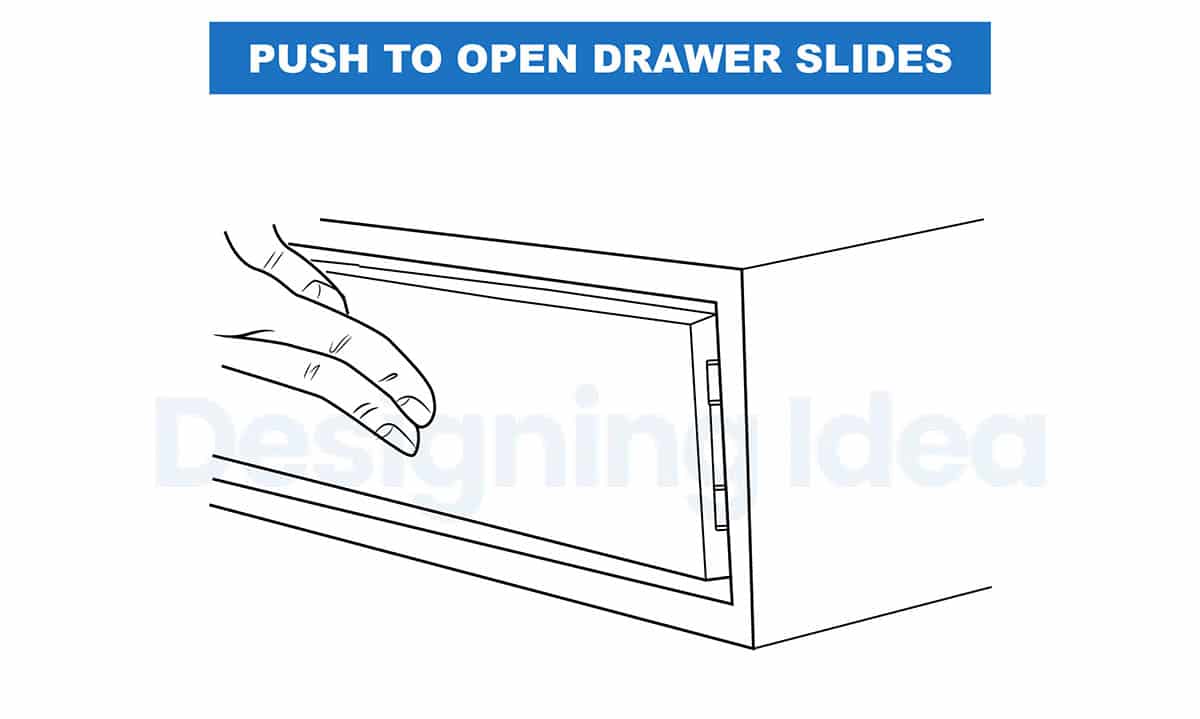

Push To Open Glides

Push-to-open glide mechanisms remove the demand for dresser pulls, minimizing exposed hardware on the cabinet’s exterior. Pushing the cabinet face opens the compartment broad enough for the spring mechanism to go inside and pull it away. This compartment track feature provides a sleek and modern look while reducing costs.

Aside from that, push-to-open cabinets are common in areas where clearance or space is restricted such as trailer homes or compact locations where a handle could collide with a piece of neighboring furniture or other structural features when opened.

The vast majority of push-to-open glide mechanisms, however, rely on a spring, which degrades over a period and is subjected to daily abuse. This implies that the spring’s strength can be lost when pushing the compartment open or once it breaks.

Another issue is that if the spring system fails and the compartment closes, it can be difficult to open it by holding the outside of the drawer. Thus, when selecting this gliding feature, it is advisable to utilize high-quality materials.

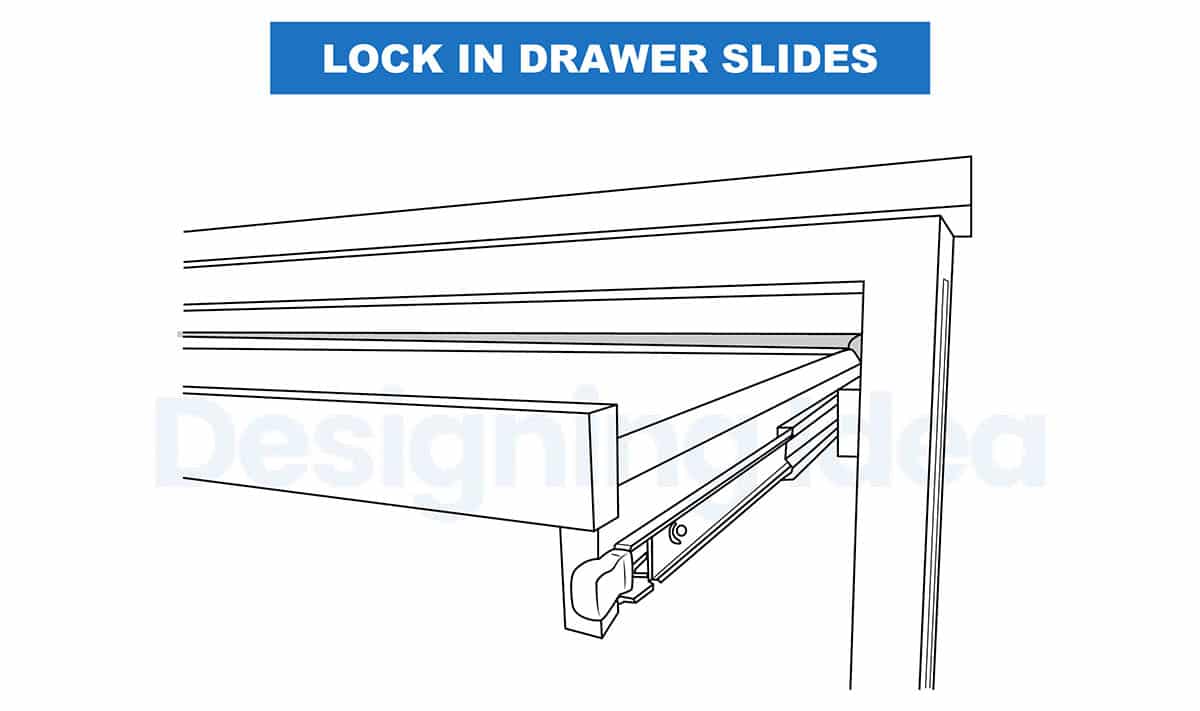

Lock In Slides

With a lock-in gliding mechanism, you can safely lock the compartment into position when closed. A locking slide feature is beneficial for kitchen appliance mounts, child safety, as well as boats and recreational vehicles where drawers may open while traveling.

The compartment remains locked or open until a lever part gets triggered.

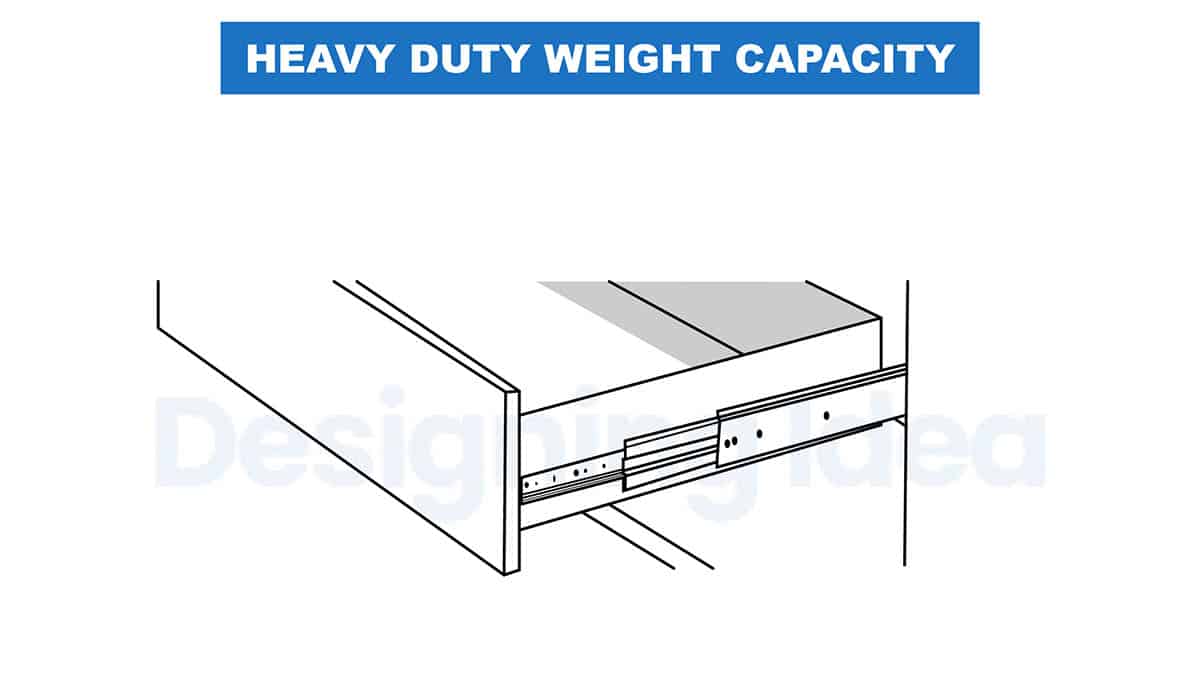

Heavy Duty Weight Capacity

Pullout hardware for cabinets that are labeled heavy-duty are indeed robust and long-lasting. These sliders are perfect for both professional and recreational use. The construction of camper trailers, caravans, vehicle coverings, and customized drawers all make use of these incredibly durable cabinet motion tracks.

Massive loads of up to 170 pounds can usually be supported by heavy-duty tracks. In fact, some of these track systems even include distinctive properties such as lock-in and lock-out features as well as weight capacities of approximately 1,300 lbs.

Anti-Rust Glides

There are some rust-resistant sliding systems available on the market. Stainless-steel telescopic tracks, chemically treated runners, and aluminum rails are among them.

These anti-rust cabinet motion tracks are ideal for cabinets located in high-moisture regions such as bathrooms.

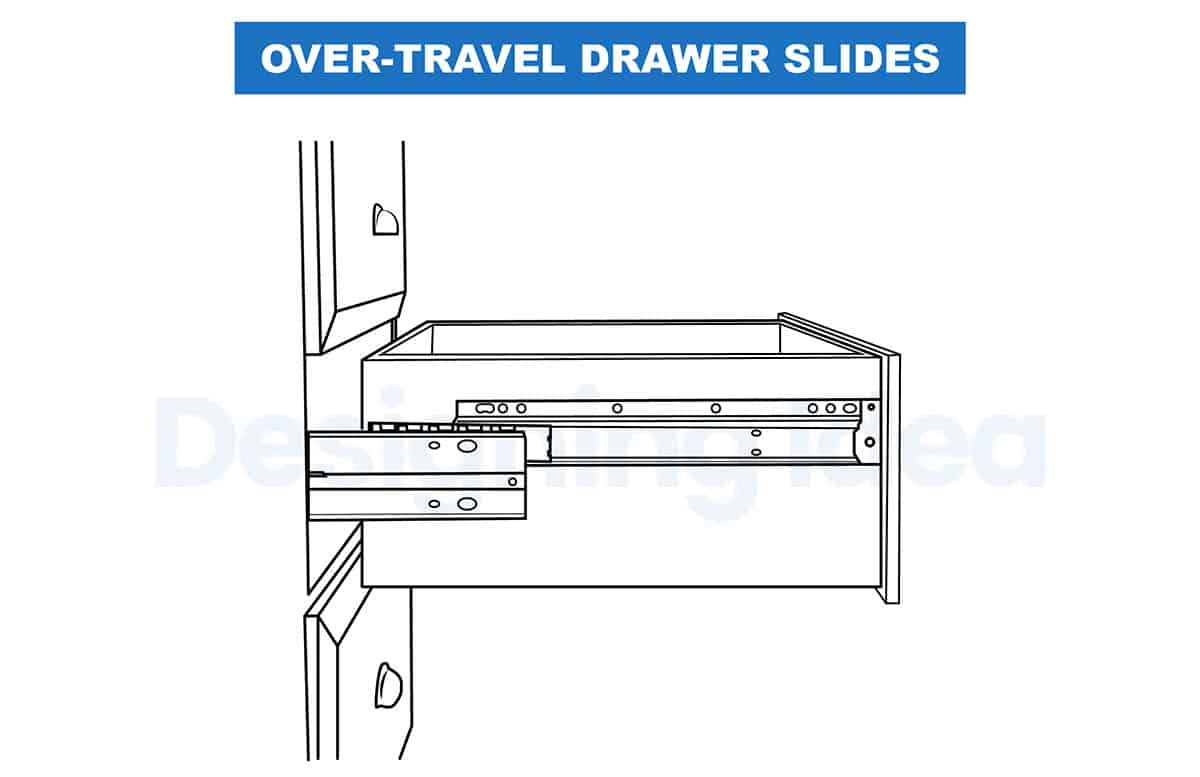

Over-Travel Glides

Over-travel track mechanisms are among the most versatile cabinet motion tracks available on the market. As a result, the compartment might stretch far beyond the front of the cabinet.

It is ideal for keeping lidded containers since it allows the cover to be completely lifted without taking the container out of the drawer.

How To Measure Sliding Mechanisms of Drawers

If your drawers stick, jam, cannot open or close at all, or produce awful noises, it is indeed likely that the tracks need to be replaced.

Understanding how to measure cabinet tracks is essential for the usage and lifetime of your drawers, whether you are putting in new drawers or repairing slider hardware on your current drawers.

To accurately measure your cabinet tracks, you will need the following items and tools:

• Measuring tape

• Screwdriver

Step-by-Step Instructions for Measuring Cabinet Tracks

Take The Drawer Out of The Cabinet: Remember that this is not the time to guess since precision is essential.

Taking out the cabinet may necessitate considerable effort. Most drawers necessitate you to completely extend the compartment before lifting it, and it will come straight out.

If this does not work, you have to guide and reposition the compartment until it is fully extended. Afterward, lift the cabinet back to release the wheels out of the supports.

If neither of these alternatives works, you might find using a screwdriver useful to remove the wheels from the supports.

Get The Exact Measurements Box Instead of the Cabinet Front: The front face of the compartment must not be measured because it serves to prevent the caddy from getting stuck in the space.

Thus, you have to begin measuring at the backside of the box and work your way forward, not including the front of the drawer.

Once you have determined the length, you have to round the figure down. For instance, if the compartment is 20.5 inches long, then you would need around 20 inches of cabinet motion tracks.

Take The Measurements Of The Drawer’s Width As Well As The Cabinet’s Opening Size: You can use full-extension slide supports if the distance between the width of the container and the width of the opening is 1/8 inches.

To ensure that the compartment functions with the new slides, you must utilize bottom-mount supports or perform some little woodworking if they are less than or greater than 1/8 inches.

Inspect The Drawer’s Exterior As Well As The Cabinet’s Interior: An imprecise installation or a poor layout could be to blame for the cabinet tracks’ sudden and unexpected deterioration.

It is possible that smaller slides were employed to prevent rubbing against a cabinet’s interior. If so, you will also need to utilize smaller slides to prevent the same problem.

Consider Taking the Storage Unit With You If, After Getting The Measurement, You Are Still Unsure About The Exact Size Of Slides To Buy: The person who is selling the cabinet tracks will almost certainly know how to measure your compartment and can help with questions and supply you with suitable tracks for your project that will fit precisely.

• Take Note: You should always consider replacing your cabinet tracks in sets. If only one part of the compartment slide is replaced, the container may be unstable.

This could shatter the cabinets or potentially trigger it to tumble out of its enclosure, which might cause damage.

Center Mounted Slides Vs Side Mounted Slides

Center-mounted cabinet tracks are a single piece that attaches to the center of the storage unit’s bottom part. Whenever the compartment is open, they are not noticeable.

Depending on the width of the slide, some might necessitate clearance. The compartment height may be restricted by center-mounted cabinet tracks, so the cabinet’s height must be taken into account.

Moreover, center-mounted cabinet rail systems have the advantage of being simpler to install. Additionally, it is concealed, giving the storage unit a more appealing appearance.

Nonetheless, storage bins constructed of light materials are frequently used with these kinds of slides. They are not heavy-duty and can only handle little objects.

Unfortunately, center-mounted cabinet rail systems are often only offered in a 3/4 extension owing to weight restrictions. Additionally, it is typically marketed as a single slide and lacks self-close and soft-close functionality.

Side mount glide mechanisms, on the other hand, are available in pairs and attach to the interior of the cabinet casing as well as the side of the case. Whenever you open the drawer, you can clearly see the slide on the side of the cabinet unit.

They necessitate arranging for clearance between the cabinet opening as well as the pull-out hardware, which is normally 12 inches between the slides and the front opening of the compartment.

Slides for side-mounted cabinets are linked horizontally to the compartment and cabinet structure. These slides, unlike center-mounted slides, can handle a significant amount of weight and survive for a very long period, making them appropriate for a wide range of situations.

They are perfect for storage boxes, multipurpose cabinets, kitchen cabinets, as well as other cabinets that hold heavy objects. Moreover, there are usually two types of side-mounted cabinet bearing hardware, which we will discuss shortly below – ball bearings and rollers.

In European variants, a nylon roller that travels along a rail is present. The benefit of the ball-bearing side-mounted slide types is that they run smoothly, can support a lot of weight, and can fully extend or over-travel.

Additionally, side-mounted ball-bearing slides frequently have a detent that prevents the caddy from opening whenever the cabinet is marginally out of alignment.

Epoxy-coated cabinets, however, contain a self-closing mechanism and an opening lock that keeps the compartment open for simple access while operating.

Ultimately, the distance between the compartment, as well as the cabinet opening, must normally be at least a half-inch for side-mounted motion tracks.

On the contrary, the only disadvantage of a side-mounted compartment slide is that it restricts the case’s lateral width.

Ball Slides Vs Roller Slides

Although there are different kinds of bureau glide mechanisms, the two most used kinds are roller and ball-bearing. Wheels are present on roller cabinet glide tracks.

Meanwhile, ball-bearing cabinet rail systems have ball bearings. In addition to this design differential, roller and ball-bearing rolling tracks differ in multiple ways.

Compared to roller glide tracks, ball-bearing rail systems offer smoother functioning. Conventional wheels are less effective than ball bearings at reducing friction.

Ball-bearing cabinets are henceforth simpler to open. Compared to roller operating mechanisms, they are easier to pull open and press closed.

Generally speaking, roller cabinet pull-out hardware are less expensive than their ball-bearing equivalents. Thus, homeowners with limited budget opt for this prevalent type of compartment slide.

They are constructed from substandard materials. Roller cabinet glide systems are frequently found in inexpensive, low-quality types of furniture styles. In contrast, ball bearings are more frequently seen in costly and luxury cabinetry.

Ball-bearing mechanisms often last much longer than roller cabinet rolling tracks as they are made of harder and more durable materials.

Steel, like cold-rolled steel, is used to make a lot of ball-bearing cabinet rail systems. They will keep rolling effortlessly even if used every day for many years.

Difference Between Soft-Close And Self-Close Drawers

Slides that self-close and soft-close share a number of properties. Meanwhile, there is one major distinction between all soft-close and self-close slides.

A self-close wardrobe slide pulls a caddy rapidly closed after the spring is activated by using a spring system to close the drawer.

Nevertheless, soft-close slides feature a dampening system in addition to a spring to silently and carefully close the drawer.

Do you have any experience with these storage unit products and accessories? Share any information, tips or questions with us in the comments below. See more related content in our article about the types of drawers on this page.