Polyaspartic Coatings for Garage Floors (Pros and Cons)

Dubbed the next generation of floor sealant, polyaspartic garage floor coating offers superior properties, making it a sound alternative to epoxy and other traditional floor coatings. A polyaspartic coating is very durable and can match any look with the variety of colors and designs available today.

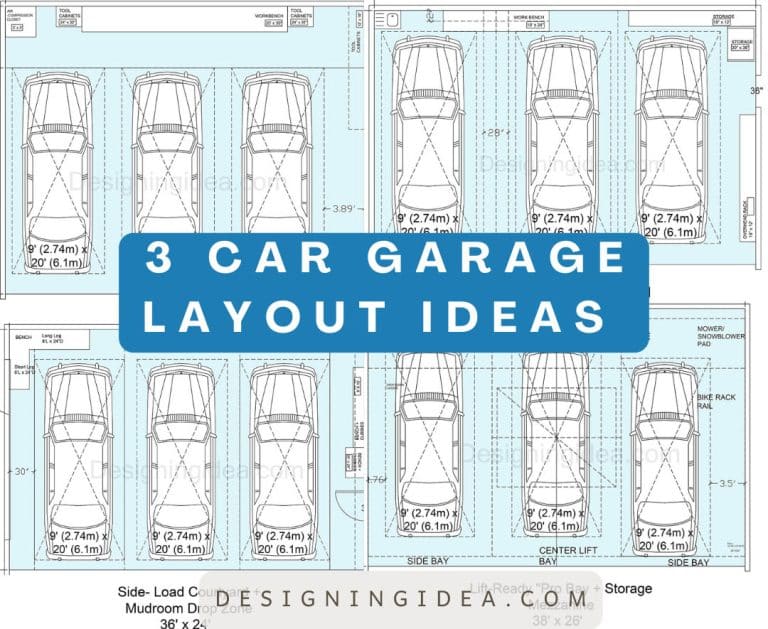

With its open space, a garage makes it an excellent multipurpose area. It can be an overflow for indoor living, a workshop, tool storage, or even a recreation space. Due to the extensive use of the garage flooring, they need a top coat that can withstand daily wear and tear.

Upload a photo and get instant before-and-after room designs.

No design experience needed — join 2.39 million+ happy users.

👉 Try the AI design tool now

What is a Polyaspartic Garage Floor Coating?

Polyaspartic garage floor coating is a type of high-performing floor covering with notable features such as fast curing, high durability, and elasticity. It has been used since the 1990s mainly for civil engineering projects such as bridges, rails, and other metal components. This extensive use of polyaspartic is mainly due to its excellent corrosion resistance and flexibility.

Since then, improvements have been made to address limitations such as moisture tolerance, making poly aspartic an excellent alternative to polyurethane coating and epoxy garage floors.

The modern versions of the polyaspartic garage floor coating made it available for commercial use in the late 90s and early 2000s. Its excellent performance on high-traffic floors and continuous improvement paved the way for polyaspartic coatings to gain popularity in residential use.

Polyaspartic coatings are also termed aliphatic polyureas. Polyurea is a type of synthetic polymer that essentially makes poly aspartic a subset of the polyurethane family. To work, it needs a resin and a catalyst to enable the curing process. Polyaspartic finishes do cost about 20 percent more than epoxies. Some companies sell polyaspartics by the gallon.

Polyaspartic Coating Pros and Cons

Here we share the advantages and disadvantages of polyaspartic coating for garage floors.

Pros

Excellent Abrasion Resistance: One of the main concerns of garage owners is scratch marks and other indentations. Polyaspartic has a unique high-cross-link density, and each polymer chain is tightly interconnected.

In addition, chemical groups that include urea and ester linkages make the coating even more robust. The rapid curing of polyaspartic floor coating is another factor that makes the floor sealant abrasion and stress resistant, where it quickly forms the properties needed for a strong material.

Does Not Stain Easily: These types of flooring applications have a sleek, watertight, and smooth surface that keeps away spilled liquid from getting into the porous concrete.

Polyaspartic top coat is a practical choice for spaces where vehicles and other work areas involve the use of petroleum and other oil-based materials. Though like any type of garage floor coating, it is advisable to wipe off the spill immediately to prevent any possibility of discoloration.

Does Not Harbor Allergens: A floor coat of polyaspartic has a very durable surface that won’t produce or trap dust. People sensitive to dust, pollen, or other allergens are recommended to use these floor coatings.

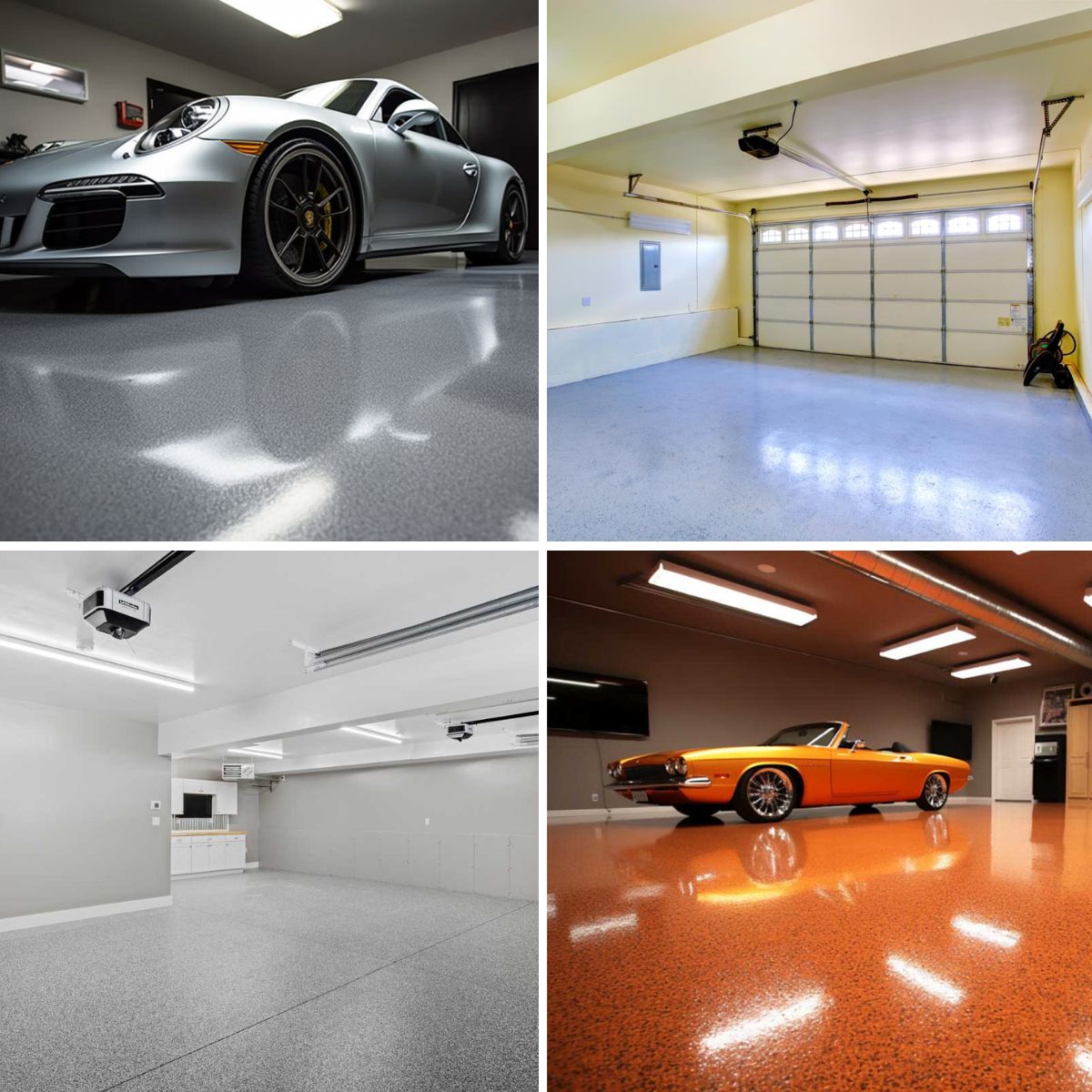

Customizable: The available colors and vinyl additives for the polyaspartic coatings for garage floors can be combined to produce the desired design. Flooring companies continue to expand the available options.

Slip Resistant: A polyaspartic coating without the added vinyl chips can look like an epoxy finish but has better traction due to its flexibility and elongation process. The faster curing process also allows the additives and the coating to bind together better while preventing air pockets from being trapped. Grip traction additives can be applied to increase the slip resistance of this floor application.

Faster Installation: Compared to other floor coatings, polyaspartic coatings cures faster. Depending on the condition of the substrate and other factors, the curing time usually takes from 30 minutes to 2 hours. After a second layer, the coating can be walked on after 5 hours.

Won’t Yellow Overtime: Most polyureas exhibit good resistance to UV degradation, but it is best to check the manufacturer’s material data sheet on the type of polyurea used. Aliphatic polyureas are resistant to yellowing, while aromatic polyurea coatings will yellow over time when exposed to sunlight.

Debonding is Unlikely: While the coating is flexible, its excellent adhesion to concrete and material stability does not cause debonding when subjected to heat. Hot tire pickup commonly occurs on garage floors, especially with poor installation of any type of floor coating.

Acceptable VOC levels: Off-gassing, even after application, is common for plastic-based materials, including polyaspartic and epoxy coatings. The difference is that polyaspartic floors have polyaspatic ester, which is the main ingredient used to react with an aliphatic hardener.

This polyaspartic ester has zero VOC, significantly reducing the harmful gasses released, especially under higher temperatures. Since curing time is faster, installers also have a shorter exposure time to the floor coating. Check for the material data sheet to confirm the floor coating VOC content.

Quick Return to Service: Due to the fast-curing time, the garage can typically be returned to regular use within a day or two after the coating application.

All Year-Round Application: Some coatings are formulated to be applied in colder temperatures, allowing for year-round use in various climates.

Cons

Initial Costs are Higher: Compared to epoxy, which is the most commonly used garage coating, polyaspartic coating costs twice more for the material. Professional polyaspartic coatings also cost more than epoxy, and since it is relatively new in residential use, it is likely there are fewer experienced installers in some localities.

Prone to Acid Corrosion: While it is resistant to most chemicals, polyaspartic coatings can corrode when exposed to acid since the molecules composed of amino acids can be broken down by highly acidic compounds.

Professional Installation: Polyaspartic coating for garage floors will need an expert installer to ensure proper installation. The floor coating is sensitive to temperature during installation, which can lead to poor adhesion and other issues that can decrease the material’s performance.

Short Pot Life: These coatings have a short pot life, meaning they have a limited working time once mixed. This can be challenging for larger or more complex projects, as it requires a quick and efficient application to avoid wastage.

Sensitivity to Environmental Conditions: Polyaspartic coatings can be sensitive to temperature and humidity during the application process. Extreme environmental conditions can affect the coating’s curing and adhesion. This detail makes it challenging to apply in certain situations, especially in a garage with no windows.

Not DIY-Friendly: Due to the fast curing and specialized equipment needed for application, these coatings are not typically suitable for DIY projects. Professional installation is usually required, adding to the overall cost.

It cannot be installed in Damp Areas: Unlike epoxy, polyaspartic coatings can be installed in damp and moist areas but not in stagnant water. This makes an excellent feature of the application when trying to install it in a garage converted to a room.

Polyaspartic Floor Coating Colors

Polyaspartic floor coatings can come plainly in solid colors or with vinyl chips or flakes added on the top layer. Solid colors usually come in earth tones and bold colors and neutrals that can serve as a backdrop for the vinyl chips added or can be left as is to achieve a solid color. Metallic, both in solid or metallic mica flakes, are also available.

Color availability and variations for the floor coating depend on the manufacturer. Most solid colors for polyaspartic floor coating come in soft earthen tones and neutrals with varying chip sizes, including 1/8″, ¼,” 1″, and 1/16″.

Neutral Colors: Neutrals are common in poly aspartic coatings and well suited for areas in a room that are visually greater. This includes various shades of gray, beige, taupe, and other neutral tones. Neutral colors are popular for commercial and industrial settings where a clean and professional look is desired.

Earth Tones: Colors from nature, such as browns, tans, and greens, are commonly used in residential and commercial spaces to create a warm and inviting ambiance.

Bold Colors: Some coatings come in bold and vibrant colors like red, blue, green, or yellow. These colors are often used for decorative purposes or to add a pop of color to specific areas.

Metallic Colors: Floor applications with metallic pigments are also available. These coatings create a unique, shimmering effect and are popular in showrooms, retail spaces, and high-end residential settings.

Customized Colors: Many manufacturers offer the option to create custom colors based on the specific preferences or branding requirements of the client. Custom color matching allows for a truly personalized floor coating solution.

Common Solid Colors: White, Mocha, Sandstone, Silver Gray, Dark Gray, Fog Gray, Pearl Gray, Black, Charcoal, and Tan,

Common Flake Options:

• Blizzard – Large chips in dark gray with beige chips with several blue flakes.

• Lime Night – Yellow, green, white, and a prominent black color.

• Greystone – Different gray hues with a white backdrop.

• Lighthouse – Mix of maroon, black, white, and a few sky-blue flakes.

• Saddle Tan – Several different shades of brown.

• Galaxy – A combination of sky-blue specks of white flakes.

Others:

• Salt and Pepper – A common pattern in flooring, the salt and pepper boasts fine white, gray, and beige colors.

• Gemstone

• Terrazzo

• Granite

• Jade

• Maui Sand

Custom: Customized colors and additives can be requested by a homeowner if offered by the manufacturer. Manufacturers offer the option to create custom colors based on specific preferences or to match an existing design. The personalized option makes the coating a desirable option for garages.

Polyaspartic Application Cost

Based on Home Advisor, the cost of polyaspartic coating for garage floors is between $6.50 to $9.00 per square foot. The cost includes the preparation, repairs needed, and the pouring of the solution and sealing garage floors. Meanwhile, A DIY installation will cost from $4.50 to $6.25, including materials and tools.

Where to Buy Polyaspartic Flooring Products?

According to Allied Market Research, the key players in the distribution of polyaspartic coatings are Laticrete, ResinWerks, Sherwin-Williams, PPG Industries, Akzo Nobel N.V., CTM Coatings, Rust-Oleum, Indmar Coatings Corporation and Covestro A.G.

ResinWerks was the earliest company to explore the development and production of polyaspartic floor coating technology twenty years ago. Today, their earliest innovations are seen in their Kinetic line of floor coatings.

Polyaspartic Floor Coating can be Bought From:

• Specialty Coating Suppliers

• Paint Stores

• Online Retailers

• Manufacturer’s Website

• Authorized Dealers

DIY Polyaspartic Garage Coating

Polyaspartic floor coating kits are available in the market that generally includes a two-part floor coating system, usually in 2 gallons to 10 gallons. Usually, companies will provide the effective coverage of a polyaspartic kit, for example, 500 square feet.

Other options are provided in the order menu where an add-on for blended flakes (in pounds) with available sizes such as 1/16″, 1/8″, ¼,” ½,” and 1″. Optional clear primer (in gallons) can also be added.

For existing concrete substrates or flooring, concrete surface preparation materials are needed. The said preparation process is critical to the success of a floor installation. Concrete preparation tools are used to include cutting solutions and concrete garage cleaning, floor grinder, and sander.

The usual equipment and tools include safety equipment, painter’s tape, plastic sheeting, and application tools. Remember that this floor coating is labor-intensive, and knowledge of the application process is needed. An extensive experience in similar projects is required.

Epoxy Coating vs Polyaspartic

Curing Time: The curing time is the time duration needed for a material to reach its optimum properties, such as hardness and protection. The advantages of a longer curing time will prevent contamination, improve adhesion, and minimize environmental influences that can affect the desired properties of the wet application.

Rapid curing will also mean lesser labor, and the polyaspartic coating for the garage floor can be used immediately.

Generally, most polyaspartic applications can dry from 30 minutes to 4 hours, depending on humidity, temperature, and other external factors. The warmer, the faster the drying time. Light foot traffic can be accommodated in 12 hours.

But while poly aspartic cures faster, its stability and workability make it ideal even for a DIY project. Meanwhile, most epoxy floor coating will require seven days to reach its full cure, and like polyaspartic coatings, the curing time is influenced by environmental factors.

Durability and Abrasion Resistance: Both epoxy and polyaspartic coatings have their strengths and are suitable for various applications. Epoxy coatings are extensively ued in industrial and commercial settings, while these coatings are well-regarded for their durability, rapid curing, and UV stability, making them an excellent option for garage floors and outdoor surfaces.

When choosing, consider the specific requirements of your project, budget, desired curing time, and the conditions of the surface being coated. Due to its excellent bonding properties, these coatings are highly durable and offer excellent abrasion resistance. They are well-suited for medium to high-traffic areas, commercial spaces, and industrial environments.

The epoxy floor is a compound of synthetic resins that provide an extremely durable, seamless floor. These floors are an ideal choice when a floor is required to withstand massive loads. – Professional Management of Housekeeping Operations, Thomas J. A. Jones

Epoxy coatings are also durable and provide good abrasion resistance. However, they may not be as resistant to abrasion as polyaspartic coatings in some cases and will need inorganic fillers to improve hardness and wear resistance. The most common additive to epoxy to improve abrasion resistance is blending in G/flex 650

UV stability: Most types of garages can be exposed to sunlight, especially when garage doors are opened frequently. Polyaspartic coatings with aliphatic polyureas components are better at resisting UV damage than epoxy. But note that there are types that will yellow over time, so it is important to check the material information before purchasing.

Epoxy coatings are known to be more prone to yellowing and chalking when exposed to UV light, so they are best suited for indoor use or areas protected from direct sunlight. UV light stabilizer can be added to an epoxy coating if yellowing is a concern.

Temperature and Humidity Sensitivity: Polyaspartic coatings are less sensitive to temperature and humidity during application, making them more versatile in various environmental conditions. However, take note that garage floor coating cannot be installed when moisture is present. The mixture will soften and will not adhere properly to the concrete and can also lead to lifting of the surface.

Epoxy coatings can be more sensitive to temperature and humidity during application, which can affect the final finish and performance. At times, a climate controlled garage will help address this challenge. But epoxy coatings can be installed in damp and wet areas except for standing water.

Pot Life Longevity: Also termed as pot life or working time, pot life is the length of time that a mixture can retain the viscosity level for it to be applied on a surface. The coatings have a short pot life, meaning they must be applied quickly once mixed as they will harden. If planning to undertake a wider garage area as a DIY project, it is best to have another person to help with the application.

Epoxy coatings generally have a longer pot life, giving more working time for application. This works well in expansive garages as it gives the installer more time to level or adjust the substrate.

Thickness and Self-Leveling: These coatings can be applied in thin layers and still provide excellent performance. They are self-leveling and can create a smooth finish, even on irregular surfaces.

This feature of a polyspartic floor coating makes it easier to level uneven flooring compared to epoxy. Meanwhile, epoxy coatings may require thicker applications to achieve the same level of performance, and they may not self-level as effectively as these coatings.

Cost: Polyaspartic coatings for garage floors are more expensive than epoxy coatings. A poly aspartic floor coat usually costs between $6.50 to $9.00 for a professional installation, and a DIY installation costs $4.50 to $6.25. Epoxy, on the other hand, can cost between $3.00 to $12.00 per square foot for a professional installation and $2.00 to $5.00 per square foot for a DIY application.

See more related content in our article about polished concrete garage floor on this page.