Should You Use Engineered Wood Siding? (Pros & Cons and Design Guide)

When it’s time to choose siding for your home, take a minute to think about the decision you’re making. Siding is exposed to the elements, seven days a week, 24 hours a day, 365 days a year. It has two important jobs.

The first is protection. Think of the siding as the skin of your home, protecting what’s on the inside and repelling what doesn’t belong. Siding should protect the contents and inhabitants from weather, such as wind, rain, sleet, and snow. It also provides a layer of insulation and supports good insulation and temperature regulation.

Upload a photo and get instant before-and-after room designs.

No design experience needed — join 2.39 million+ happy users.

👉 Try the AI design tool now

It’s not just the weather you need protection from, though! Siding should not only keep the inside of your house clean and dry, it must keep pests out. Termites and other pests can do a lot of damage in a short period of time, and are costly to remove. Don’t forget about fungal damage. Artillery fungus, which looks like small black dots, commonly affects siding. It is aptly named because it shoots its spores up to 20 feet away, and can be very persistent and difficult to eliminate once it takes hold.

The second job of siding is to be the face of your home. Real estate agents use the term ‘curb appeal’ to describe how attractive a home looks from the sidewalk, from the point of view of a prospective buyer. Since so much of your home’s surface will be covered with siding, it is important to make a choice that is pleasing to you and maintains or increases the value of the home.

Some homes don’t require siding. Masonry homes, for example, do not require siding. This method of construction effectively seals and protects the inside of the home from the elements. However, siding is often added to masonry homes as a purely aesthetic choice. An internally framed house will always require siding. Since most new-construction homes are internally framed with wood, most homeowners or renovators will need to make a decision about siding.

Engineered Wood Exterior Siding

Engineered wood siding is a modern solution to an ancient problem — how to keep the insides of homes comfortable, dry, and pest-free. Over time, humans have used every material possible to solve this problem, from animal skins to mud and snow, to brick and wood. Now, technology has brought us an innovative and environmentally friendly solution: engineered wood siding.

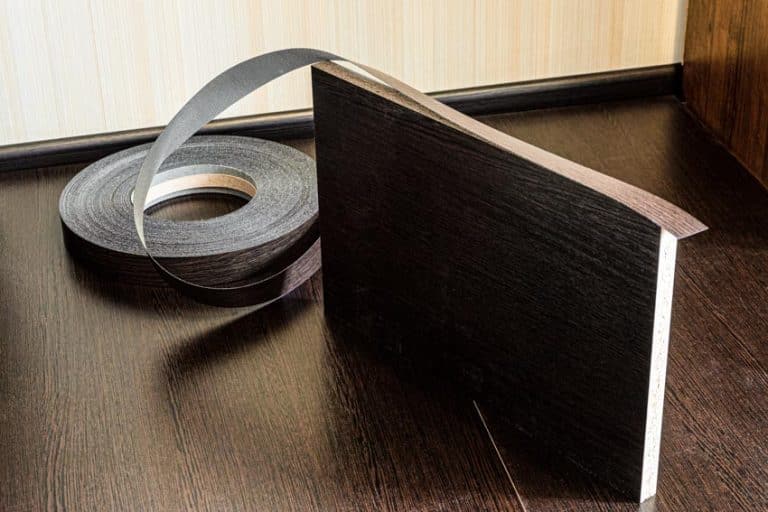

Engineered wood is a manufactured product. It begins with real wood byproducts, such as chips or fiber strips. Some brands use pre-consumer recycled wood products for an extra boost of eco-friendliness. The wood parts are mixed with a specially formulated adhesive resin. At this stage in the process, other compounds or substances can be introduced to reduce susceptibility to pests and/or rot. The compounds and substances added depend on the brand manufacturer. In the final stage, the appearance of the finished product is carefully considered. The resin and wood material is molded and pressed into a uniform plank shape.

Consumers have the option to purchase material that is pre-primed and ready to paint, ready to stain, or even pre-finished boards. A textured wood grain pattern can also be added for an even more realistic wood appearance. The finished planks are cut and sold in standard lengths, usually 16 feet. Some brands offer planks of multiple thicknesses and depths for further customization and versatility.

Wood Composite Siding Pros and Cons

The engineered wood siding looks great and performs well where it matters — keeping pests, rot, and moisture out. But there are many other benefits to choosing this type of siding. One of the best things about engineered wood siding is its low cost. At about half the price of natural wood, and with lower installation and maintenance costs, engineered wood is undoubtedly one of the most cost-effective choices of siding material.

Consumers concerned about their impact on the planet choose engineered wood siding because it responsibly and judiciously uses a renewable material. Pieces of wood that are not suitable for planks can be broken down into the wood chips and fibers used to make engineered wood, eliminating wasted wood.

Engineered wood siding usually includes a lip or ledge to make installation easy, quick, and accurate. It’s also much lighter than regular wood, reducing the risk of injury or harm during installation. Pre-finished versions don’t need to be primed, painted, or stained, meaning that half the labor of installation is done before the plank even leaves the factory!

One of the hardest parts of any construction project is recognizing you have to order more raw materials than you intend to use. Inevitably, there will be wastage, miscalculations, or substandard materials. Since this type of siding is so highly standardized, contractors can count on being able to use every plank they order. The benefit to you as the homeowner is beautiful, professionally installed siding, minimal joints, and greatly reduced material wastage.

Engineered wood siding is easy and convenient to order and install. With innumerable paint and siding color options, customization is also easily achieved. Your siding and trim don’t have to be the same color, for instance! Unlike choosing a paint or stain to be applied after the siding is installed, you’ll be able to see actual samples of the finished product before making your selection. Pre-finished engineered wood siding is highly standardized, so a consistent color and pattern are guaranteed.

It’s also incredibly long-lasting. Expect your engineered wood siding to stay in good condition for 20 to 30 years! Most brands offer a 30-year warranty — three decades of peace of mind, and freedom from worrying about your siding again.

In terms of drawbacks, there aren’t many. All siding can be susceptible to moisture, and engineered wood siding is no exception, though it’s much more resistant to rot than natural wood. One of the biggest drawbacks is it’s not natural wood. So you won’t get the wood grain variation and character that real wood offers. The only reason not to use engineered wood siding is a strong personal preference for a different material.

Reconstituted Wood Siding Cost

Engineered wood siding can represent significant savings over other siding options. The cost of engineered wood siding will vary depending on your location and the quality of materials. However, it typically ranges from $2.00 to $3.75 for materials, with installation costs ranging from $3.50 to to $10.00 per square foot. That puts the total cost for materials and installation at approximately $5.00 to $13.00 per sq. ft. At this rate, a 1500 square foot home would cost about $9750 in materials and installation fees.

Stucco is generally the most expensive siding option. When compared to natural wood siding, engineered wood siding is about half as expensive. And that’s just purchasing the material. Read more about stucco vs siding here. Engineered wood siding is easier to install than any other siding option, including natural wood, stucco, stone, or masonry. A faster installation process equals lower labor costs.

The final cost to be considered is maintenance and replacement. Engineered wood is one of the longest-lasting siding options and usually comes with an extensive warranty. With peace of mind should anything happen, all you need to do is visually inspect the siding by walking around the home once a year. Engineered wood siding can be cleaned with soapy water and a brush — no need to rent a pressure washer.

Keep any bushes, trees, and shrubbery should be kept trimmed, and no mulch should touch the siding. This will keep your engineered wood siding in great shape throughout its life.

Wood Veneer Board Siding Colors

The house color options for engineered wood siding are nearly endless. For a natural wood look, choose a textured wood finish and pair it with a natural wood stain. Because cedar shingles are so popular for siding, many brands offer finishes specifically designed to mimic this distinctive look.

Each brand offers its own catalog of paint colors. If you choose one of these colors, your engineered wood siding will arrive already painted and ready to install. If you’d prefer a specific paint color, and find that the manufacturer doesn’t make siding in that color, don’t worry. You always have the option to paint the planks yourself or hire someone to do it for you.

Consider paying for pre-primed boards. This not only leaves you with less to do, but it also ensures the surface you are painting will accept paint consistently, reducing the risk of blotches or patchiness. Most paints and stains will fade with time and exposure to the wind, rain, and sun. The parts of your home that get the most sunlight are likely to fade more quickly than those in the shade. Choosing exterior paint with UV protection can help slow the fading process and keep your siding shining bright.

Engineered Timber Siding Brands

Many brands are selling engineered wood siding, and more enter the market each day. Here are some that stand out.

KWP

KWP offers a 50-year warranty, outstripping some other brands by as much as 20 to 30 years. They are an established brand, with over forty years in the marketplace, and are known for their environmentally friendly practices and the exceptional durability of their products.

Their ‘Ecoside’ collection uses 100% pre-consumer recycled content. Rather than zinc borate, the traditional choice for preserving and protecting engineered wood siding, KWP has developed a proprietary resin to protect against pests, weather, and even fungus.

Truwood

Truwood has been family-owned since 1855. Their engineered wood is treated with an ecologically friendly formulation of zinc borate. Truwood offers more combinations of color, texture, length, and width than any other engineered wood siding brand.

Truwood stands behind its product with a 30-year warranty. One distinctive product is their reversible trim. Available in six widths and three thicknesses, one side is smooth, while the other is textured. This allows ultimate flexibility and versatility during the design and installation process.

LP Smartside

LP Smartside is a third well-known brand. Unlike Truwood or KWP, LP Smartside uses an overlay to coat their product, as a final step. This may provide extra protection but also increases the risk of delamination. Delamination occurs when the top layer of engineered wood siding begins to detach from the core, causing lumps or bumps to appear.

Consumer reports are mixed about the durability of LP Smartside, with many having no issues at all. LP Smartside, like KWP, offers a 50-year warranty, with a 5-year warranty on the primer/paint/finish.

For a longer-lasting finish, consumers can choose to have their LP Smartside products sent to Diamond Kote for finishing.

Metal oxide colorants are extracted from rocks and then formulated into advanced paint, which is then applied to LP Smartside products before delivery and installation. This specialty finish has a 30 year no fade warranty.

Plyboard Siding vs Fiber Cement

From a distance, it would be difficult to tell the difference between fiber cement and engineered wood siding. Both are available in a wide variety of colors, textures, and finishes. Both are cut to uniform lengths, widths, and depths, and installed in planks, similar to real wood siding. Engineered wood siding is composed of wood chips and resin.

Fiber cement siding uses cellulose or wood fibers, too, but instead of resin, these materials are mixed with sand and cement and formed into planks. The planks are then cured, which removes much of the moisture. The finished product is durable, resists warping, and will readily accept paint.

Fiber cement is often touted as an alternative to engineered wood siding, but it is important to consider the drawbacks. First, fiber cement releases silica dust when cut. Lung protection is essential for anyone in the area during construction, and special tools are required to make the cuts. Engineered wood does not require special tools or special protective equipment. Second, fiber cement is much heavier than engineered wood. It’s even heavier than natural wood. Each board must be carried and installed by two people, which can increase the installation time and cost. It must be professionally installed.

When properly installed, fiber cement siding has similar moisture-protection properties to engineered wood. However, the risk of imperfections or mistakes during installation is much higher, and the results can be catastrophic. In the worst-case scenario, moisture and rot can enter the central structure of the house, causing instability and even danger.

Engineered wood siding isn’t immune to installation mishaps, but they are less likely. This is thanks to the way they are designed. A lip or ledge on each board helps the installer line them up properly with very little effort. When the two boards are properly aligned, these lips or ledges form a seal to keep moisture out. For more related content visit our page on stucco house designs here.

Thank you for clearly explaining how engineered wood siding is used and the kinds of benefits you can get when using it. A material that rarely warps or cracks could help give my house the appearance I’ve always wanted it to have especially if it can mimic the look of wood. I’ll start browsing around the area for any siding contractors that offer engineered wood siding and have them stop over for some installations.