Garage Workshop Layouts: Best Tool Placement for Better Workflow

Getting all of your tools and equipment to fit into a garage workshop can be a frustrating experience, especially if you’re also using it to park a car and store all of the stuff you’ve accumulated. Rather than constantly dragging items out of the way just to make one cut, with the right floor plan, you could arrange it so the space works for your needs. The difference isn’t just the garage’s size; it’s tool placement, your storage systems, and workflow. In this guide, I share five practical garage workshop layouts that organize your space for jobs like milling, cutting, joinery, and assembly. These plans will help you place all the big tools where they’re needed, while keeping your walkways free to make your shop feel bigger and run more smoothly.

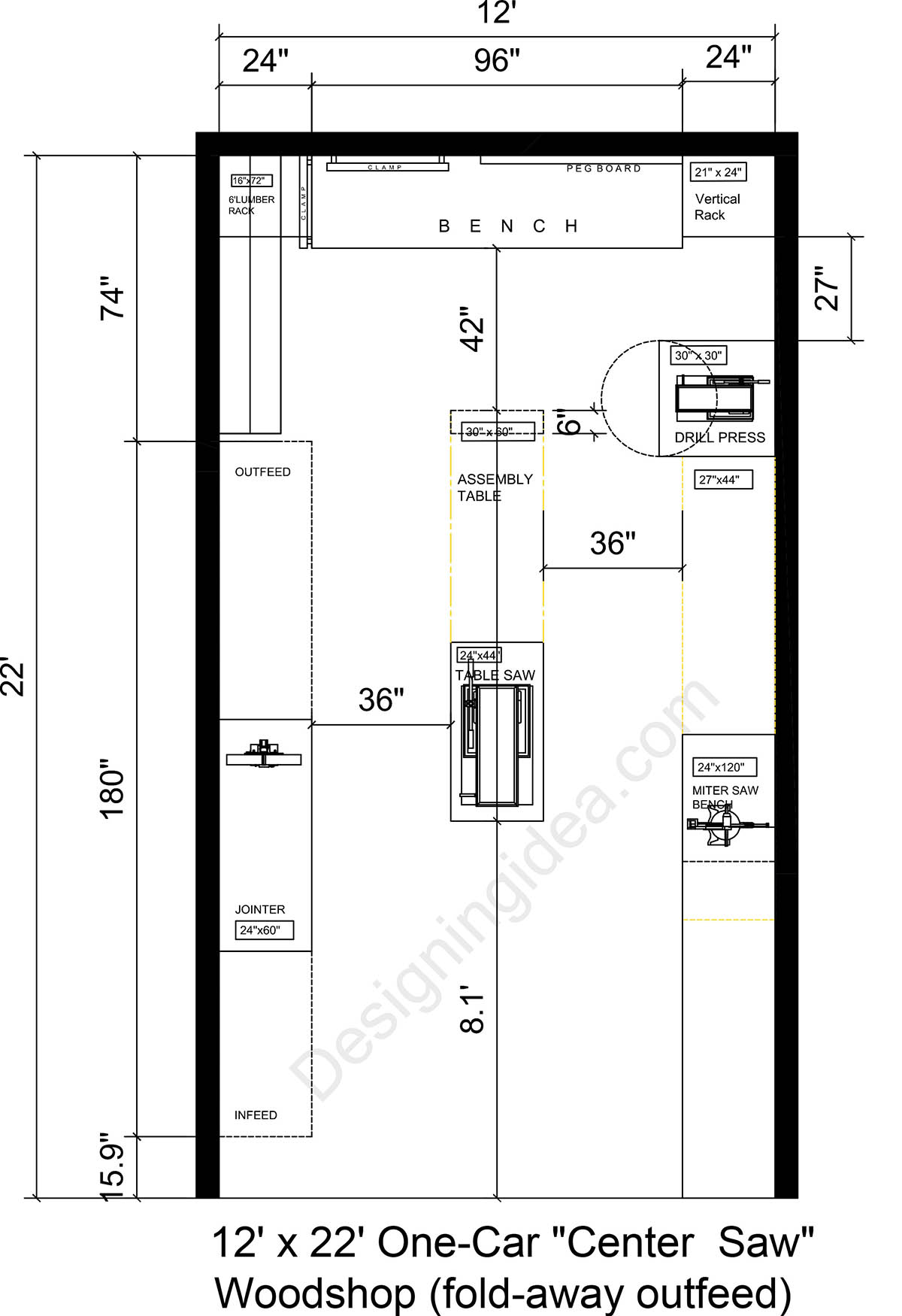

12×22 One-Car Garage With Center Saw Woodshop Layout

This garage workshop centers the table saw and lines the walls with dedicated stations, so the 12×22 layout keeps cutting lanes free, with a sensible workflow, and tools that are easy to reach.

Upload a photo and get instant before-and-after room designs.

No design experience needed — join 2.39 million+ happy users.

👉 Try the AI design tool now

- Overall garage/shop size: 12′ × 22′

- Back-wall bench length: 96″ (8′) in the center, with 24″ zones on each side

- Table saw footprint: 24″ × 44″

- Assembly table: 30″ × 60″ (aligned with the saw as a support/outfeed surface)

- Clearance between back bench and assembly table: 42″

- Main aisles around the saw: 36″ (both sides shown)

- Miter saw bench: 24″ × 120″ (10′)

- Jointer: 24″ × 60″

- Drill press footprint: 30″ × 30″ (with clearance for working shown around it)

- Lumber rack (back-left): 16″ × 72″

- Vertical rack (back-right): 21″ × 24″

- Long feed/runway length shown in the center lane: 8.1′

- Left wall (from door back): 6′ lumber rack (16″ deep, 18″ min to ceiling) → 8″ jointer (24″×60″; 4–6′ infeed/outfeed) → 13″ planer on flip-top cart (24″×22″; 36–48″ infeed/outfeed)

- Right wall: 8–10′ miter-saw station centered on wall (24″ deep bench; leave 10–12′ total span for long stock) with stop block/measure tape

• Drill press at rear third (30″×30″; give 30″ swing clearance) - Center: Table saw (27 24” ″×44″ top) set longways; fence parallel to the length of the garage.

• Outfeed: 36″-high folding outfeed/assembly table (30″×60″) that folds down to 6″ depth when parking is needed. - Back wall (22′ line): 8′ hand-tool bench (24″–30″ deep) with pegboard above

• Small parts storage drawers under bench; clamps on vertical rack at end

- Keep the table saw in the center with space around it for movement and materials.

- Don’t park any carts or bins in the 36-inch lanes.

- Use the assembly table as your outfeed and landing zone. Set its height to match, or be just below the saw table.

- Add a smooth top to the assembly table so plywood slides easily across it.

- Put the jointer on a mobile base if possible.

- Use the miter bench as a measuring station. Add a stop block system, a fence, and wall-mounted storage above it for tape measures, squares, pencils, fasteners, and bits.

- Use the back-wall bench for hand tools and small parts. Hang a pegboard above it, but avoid deep cabinets that can make the bench feel tight. Shallow shelves and labeled bins work well.

- Place the drill press in the corner and plan for its swing and keep the area clear so you have room to handle wide workpieces.

- 240V drop (ceiling cord reel) at table saw; 20A 120V along both walls every 6′

- 5–2 HP dust collector in back-left corner; 4″ flex to jointer/planer; overhead 4″ to table saw if possible

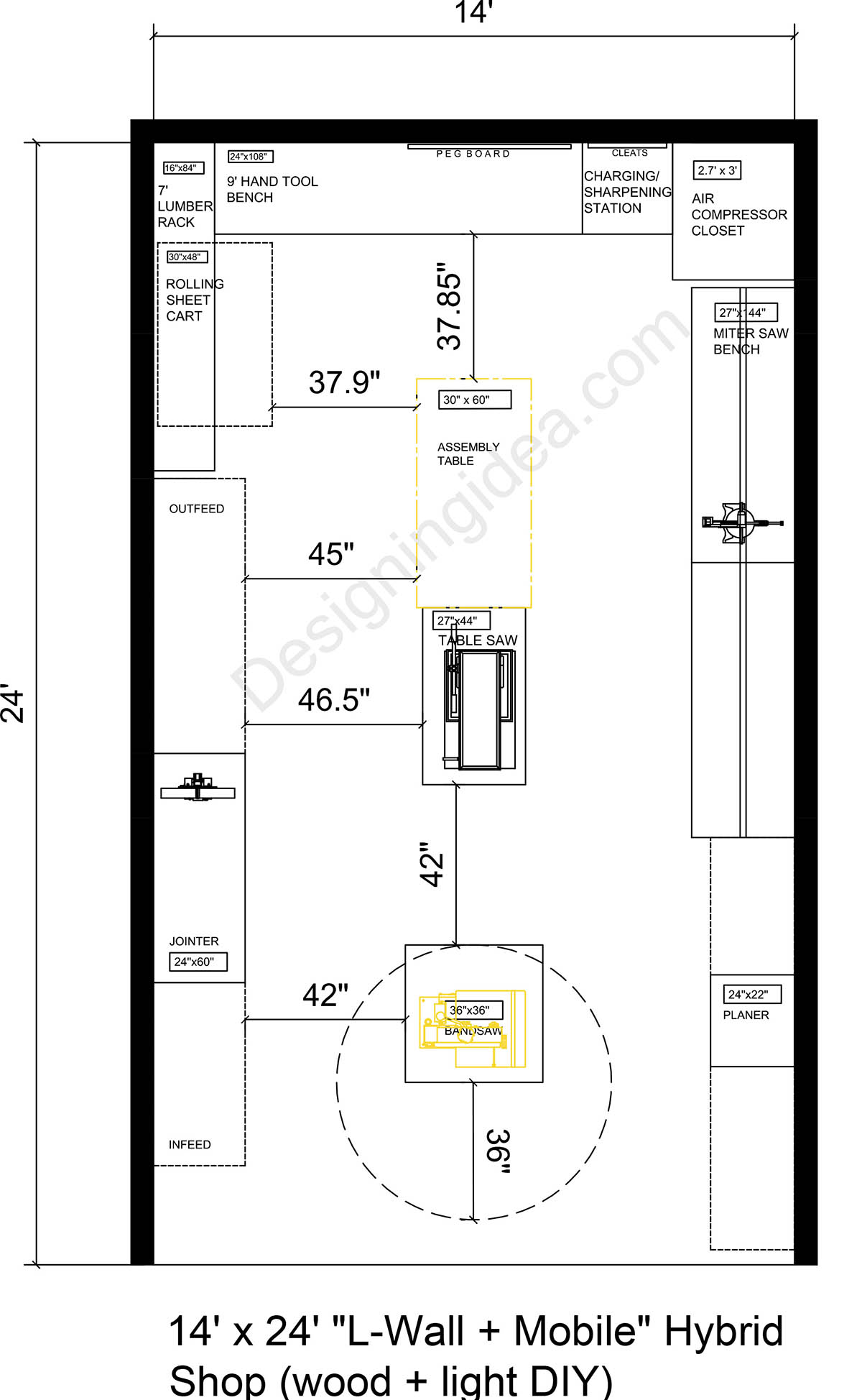

14×24 Garage Woodshop With L-Wall & Mobile Hybrid Tool Layout

This layout works because one wall handles storage and daily tasks, while mobile tools in the center keep the floor open for long boards and flexibility.

- Overall shop size: 14′ × 24′

- Lumber rack: 7′ long (16″ × 84″)

- Hand tool bench: 9′ long (24″ × 108″) with a pegboard above

- Rolling sheet cart: 30″ × 48″

- Table saw footprint: 27″ × 44″

- Assembly / outfeed table: 30″ × 60″

- Miter saw bench: 27″ × 144″ (12′ run)

- Planer footprint: 24″ × 22″ (with a long feed zone shown)

- Jointer: 24″ × 60″ (with infeed lane)

- Band saw zone: 36″ × 36″ machine footprint with a large working area in the circle, as shown

- Air compressor closet: 2.7′ × 3′

- Key clearances called out in the plan: ~37.9″, ~37.85″, 45″, 46.5″, and 42″ working lanes (varies by station)

- Left wall (24′ run): 7′ lumber rack (high) over rolling sheet cart (30″×48″) jointer (24″×60″) bandsaw (36″×36″)

- Back wall (14′ run): 9 to 10′ hand-tool bench with vise; charging/Sharpening station at one end; pegboard and French cleats above

- Right wall: 12′ miter-saw station with T-track fence and dust hood; shop-vac dock under the wings, planer on flip-top cart and air-compressor closet (3′ 2.7’ ×3′) with sound insulation near back corner

- Center: Table saw oriented lengthwise with 3′ to 3′6″ aisles both sides; 30″×60″ assembly table behind saw doubles as outfeed

• Mobile router table and spindle sander dock along aisle; roll out when needed

- 240V for table saw & jointer; 120V every 4–6′ on tool walls; ceiling cord reel over assembly

- 2HP dust collector back-right corner; 4″ main along right wall, drops to miter hood, bandsaw, jointer/planer; 2.5″ to small tools

- Set the assembly table in line with the saw so it functions as outfeed and staging.

- Keep center tools on mobile bases, even if parked. In a hybrid garage, being able to roll the saw or band saw 12 to 18 inches can make the space more usable.

- Use the L-wall for everything that doesn’t need full access from all sides.

- Accessories like hand tools, fasteners, chargers, glue-ups, sanding supplies, and measuring tools should stay at the back wall bench to keep the center clear.

- Respect the infeed and outfeed lanes for the jointer and planer. They are on opposite walls, so long boards can run straight down.

- Sheet goods belong on the rolling cart, not leaning in a corner. This layout makes breakdown easier: roll sheets near the saw when needed, then return them to the lumber rack.

Dust Mitigation: Place a small dust collector or shop vac with a separator near the right wall so it can serve the miter saw, planer, and table saw with short hose runs.

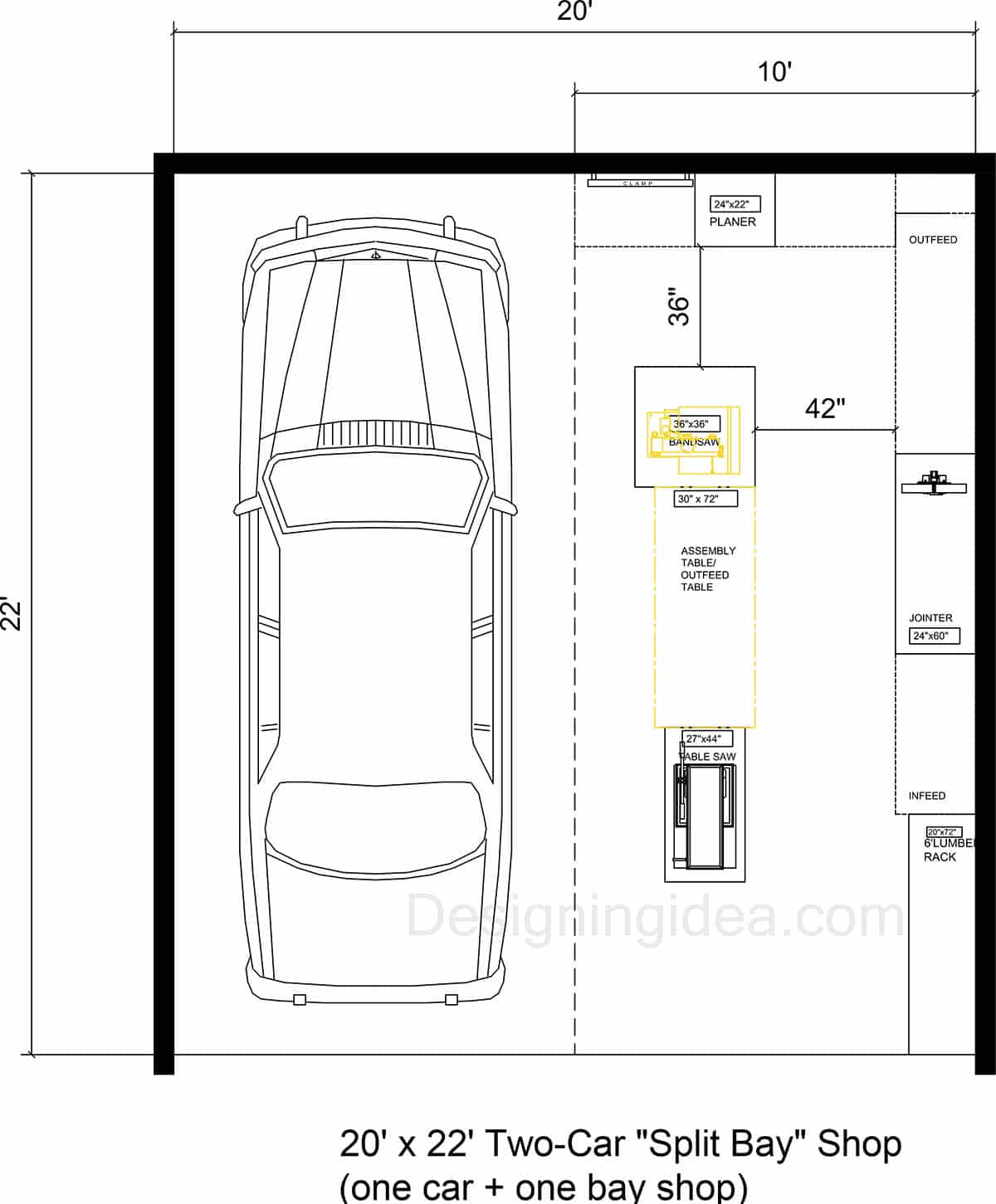

20×22 Two-Car Split Bay Garage Workshop Layout

This garage uses a split-bay layout that places a table saw at the center of the workflow in a 10ft shop lane and keeps the other half open for car parking.

- Overall garage size: 20′ × 22′

- Split-bay widths:

- Car bay: ~10′ wide (left half)

- Shop bay: ~10′ wide (right half)

- Table saw footprint: 27″ × 44″

- Assembly / outfeed table: 30″ × 72″

- Band saw footprint: 36″ × 36″

- Planer footprint: 24″ × 22″

- Jointer: 24″ × 60″ (with infeed lane shown)

- Lumber rack: 20″ × 72″ (6′ rack)

- Clearances shown:

- 36″ between the back-wall station area and the band saw zone

- 42″ working/walk clearance between the center tools and the right-side wall zone

- Left bay (10′×22′): vehicle parking kept free with fold-flat wall storage only.

- Right bay (10′×22′): the full workshop lane

- Right wall (door to back): Vertical lumber rack (20″ deep, 7′ tall) to jointer bandsaw

- Back wall (20′ span, right half usable): planer (flip-top) clamp rack + parts drawer, 6 to 8′ bench; finishing cabinet (36″×24″) on far right

- Center of shop bay: Table saw set parallel to the garage length, centered in the 10′ width; 36″ aisles on both sides inside the bay

• Rolling assembly/outfeed table (30″×72″) directly behind saw - Shared center column (between bays, if any): French-cleat tool panels (4′×6′) above the car door height so doors don’t hit

- New sub-circuit if possible: 1×240V (saw), dedicated 20A for dust collector

- 5–2HP dust collector back-right corner with 4″ main down the right wall; blast gates at each station

- Car bay outlets mounted high for chargers; keep floor clear

Noise control: If possible, put the loudest tools (planer and jointer) on vibration pads and keep hearing and eye protection at the entry to the shop bay so you use it. Keep one parking bay and dedicate the other to the shop.

- Protect the parking half with a physical boundary, which can be a floor stripe, low curb, stop, or rolling cabinet on the shop side.

- Use the 30″×72″ surface for outfeed support, assembly, sanding, and staging. Add storage underneath, to keep necessities nearby.

- Put the table saw on a mobile base so you can move it 6 to 12 inches to prevent bumping the car-side boundary.

- Keep milling tools on the perimeter and feed them through the open space.

- Add a small rolling cart for blades, push sticks, and layout tools near the saw to help keep it efficient without adding clutter.

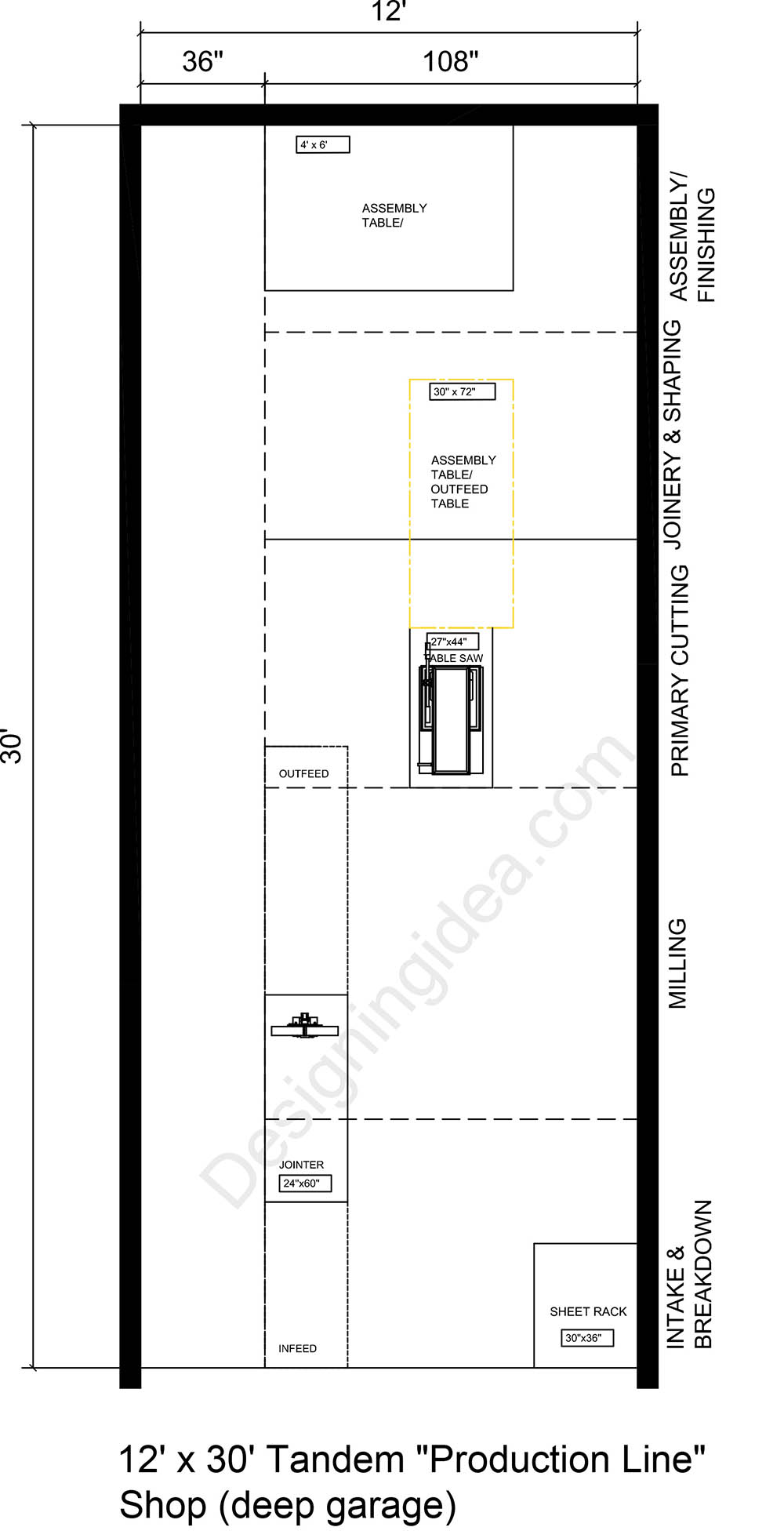

12×30 Tandem Garage Production Line Shop Design

This layout works because it turns a narrow tandem garage into a production line, keeping material moving forward and straight through from rough stock to finished assembly without the constant need for shuffling your tools around.

- Overall shop size: 12′ × 30′ (tandem/deep garage footprint)

- Main width breakdown shown at the back wall: 36″ + 108″ = 12′ total

- Primary assembly table (back of shop): 4′ × 6′

- Table saw footprint: 27″ × 44″

- Assembly / outfeed table behind saw: 30″ × 72″

- Jointer: 24″ × 60″ (with a long infeed lane)

- Sheet goods rack: 30″ × 36″

- Outfeed zone indicated (left-middle): labeled “OUTFEED” area for supporting long rips/cuts

Linear workflow zones: (front to back)

- Intake & breakdown (0′–6′): Vertical sheet rack (30″×36″) + track-saw cutting area; wall-mounted fold-down support table

- Milling (6′–14′): Jointer opposite planer, staggered so infeed/outfeed lanes don’t collide (leave 5–6′ lanes)

- Primary cutting (14′–20′): Table saw centered with 36″ side aisles; permanent 30″×72″ outfeed/assembly table

- Joinery & shaping (20′–25′): Router table, bandsaw, drill press along right wall; small parts bench left wall

- Assembly/finishing (25′–30′): 4′×6′ assembly table; wall-mounted drying rack; finishing cabinet with exhaust fan (window or door)

Power & dust:

- 2–3HP dust collector at very back-left corner pulling a 4–5″ main overhead to each zone; drops with blast gates

- 240V at saw and jointer; 120V duplexes every 4′ along both walls; two ceiling cord reels over zones 3 and 5

- This plan only works if the lane in the middle stays open for feeding boards through the jointer and table saw.

- Use the 30″×72″ table as both outfeed and staging, and match its height to the table saw or slightly lower.

- Add a slick top, laminate, or hardboard to the tabletop, so plywood slides without catching.

- Stage sheet goods near the intake end as shown. Keep a track saw and foam board or a folding cutting table nearby to rough-break plywood before it hits the table saw.

- Put joinery and shaping tools on carts in the mid-to-upper zone.

- Place your router table, benchtop sander, drill press, and small tool stands along the walls and roll them into the open lane only when needed.

- Separate clean work from dusty work. Use the 4’×6′ assembly and finishing table as a no-cut zone. Store your glue, clamps, finish supplies, and sanding blocks up there.

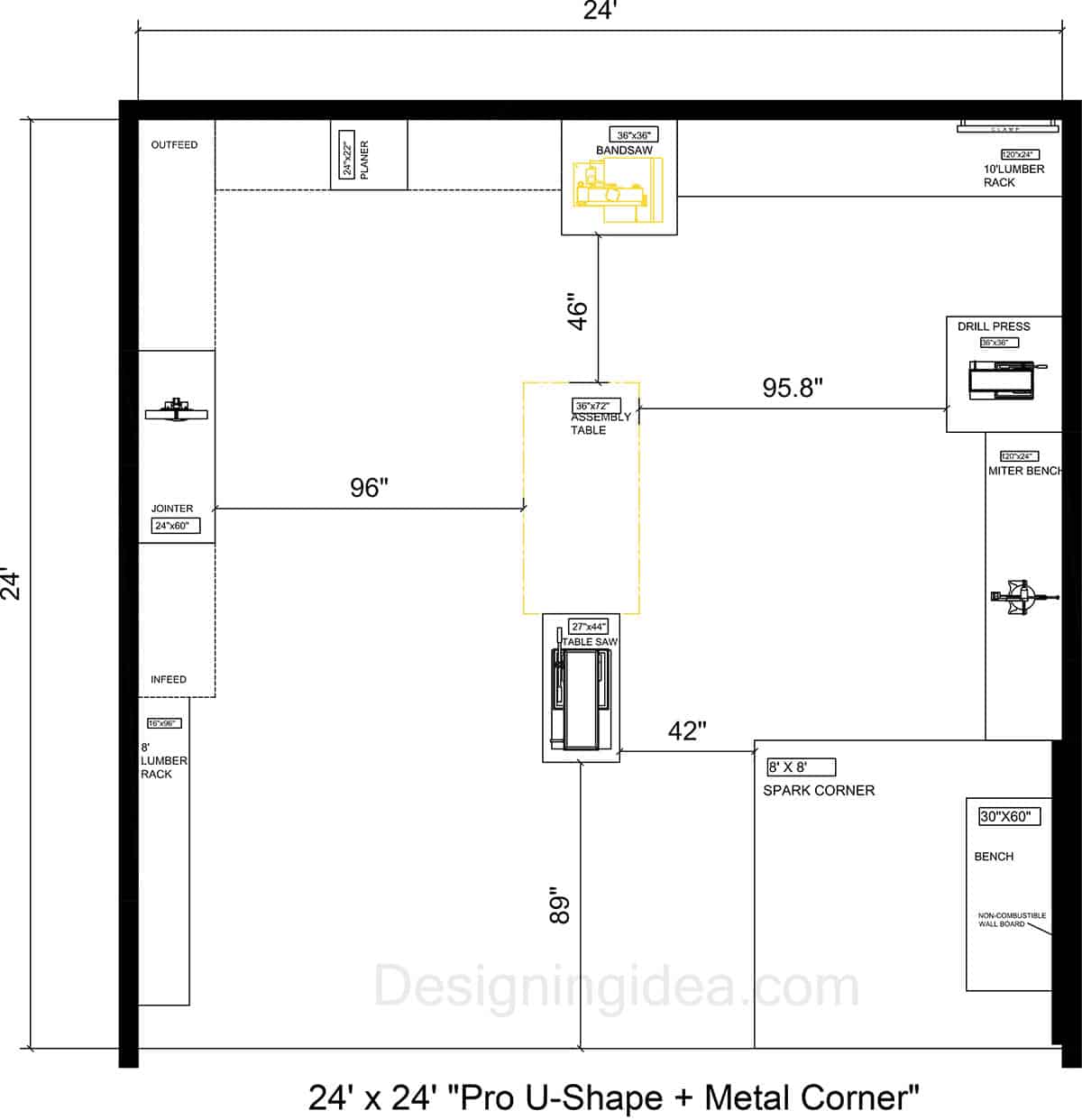

24×24 Two-Car Garage With U-Shape For Woodworking & Metal Shop Corner Layout

This layout works because the U-shaped woodworking workflow stays efficient and open around a central saw and outfeed table, while the separate 8’×8′ spark corner lets you do metalwork without turning your whole shop into a safety hazard.

- Overall garage/shop size: 24′ × 24′

- Table saw footprint: 27″ × 44″

- Assembly table (center): 36″ × 72″

- Bandsaw zone: 36″ × 36″

- Planer footprint: 24″ × 22″

- Jointer: 24″ × 60″ (with infeed lane shown)

- Miter bench: 120″ × 24″ (10′ run)

- Drill press zone: 36″ × 36″

- Lumber rack (left): 8′ rack (16″ × 96″)

- Lumber rack (top-right): 10′ rack (120″ × 24″)

- Metal “spark corner”: 8′ × 8′

- Metal bench: 30″ × 60″

- Key clearances shown:

- 96″ between jointer zone and center assembly table

- 95.8″ between assembly table and drill press zone

- 46″ between bandsaw zone and the assembly table

- 42″ walkway between the table saw area and the spark corner boundary

- 89″ open run shown in the lower center lane

- U-shape woodworking along three walls: Left wall: 8′ lumber rack over sheet cart to jointer to planer (flip-top) to bandsaw

• Back wall (U base): 10–12′ hand-tool bench centered with twin vises; clamp wall; sharpening sink or tray at one end

• Right wall: 12′ miter-saw station with dust hood and storage below; drill press near rear corner - Center island: Table saw with outfeed/assembly table (36″×72″) behind; keep 42″ aisles all around

- Front-right “spark corner” (8′×8′) for light metal/repair: Small welder and grinder on a steel bench (30″×60″) with non-combustible wall board; dedicated fire extinguisher; spark curtain; store flammables in a rated cabinet

- 3HP cyclone dust collector back-left corner; 6″ main around the U with 4″ drops

- 240V at table saw and jointer/planer; 120V every 4′ along walls; ceiling reels over island and metal bench

- Compressed air lines around perimeter with quick-disconnects; water bucket and metal bin in spark corner

- Use the 36″×72″ surface as your outfeed, and staging table, and set it at saw height or slightly lower. Be careful that it doesn’t become a catchall storage area.

- Put the planer where it can shoot long boards safely. The top wall location works best if you keep the dashed-outfeed lane empty.

- Make the right wall a precision cut wall. The 10′ miter bench is ideal for stop blocks and repeat cuts. Mount a fence, add a flip-stop, and store measuring and marking tools directly above.

- The drill press needs elbow room, so keep the 36″×36″ zone open so you can rotate wide workpieces without hitting the miter bench.

Dust collection: Metal sparks and fine wood dust are a bad combination. Store all of your flammables (finishes, rags) on the opposite side of the shop. Put your main collector or vac on the woodworking side near the table saw and jointer path. For the metal corner, sweep and use spark-safe methods.

- Table saw top: 27″×44″; allow 8′ outfeed for sheet goods

- Miter-saw bench: 24″ deep; 10–12′ total width preferred

- Jointer (8″): 24″×60″; 4–6′ infeed/outfeed lanes

- Planer (13″ lunchbox): 24″×22″ cart; 36–48″ infeed/outfeed

- Bandsaw (14″): needs 36″×36″ footprint + 36″ clearance arc

- Drill press: 30″×30″ with 30″ swing

- Benches: 34–36″ high; 24–30″ deep

- Aisles: 36–42″ target in active zones

To see more related info, visit our three car garage designs here or check out our garage plans at our store.